Why White TPO Roofing Dominates Commercial Roofing in Texas

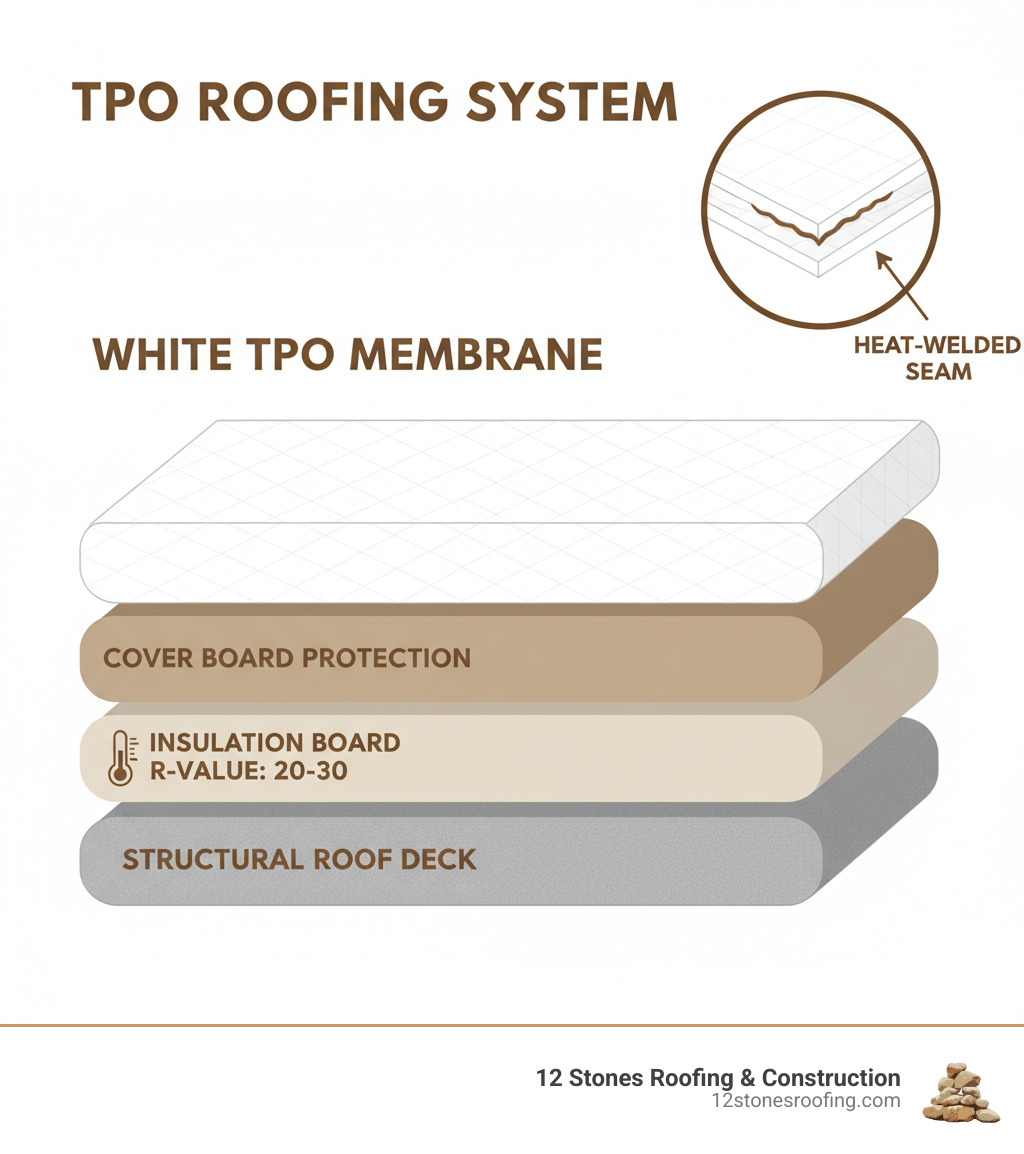

White TPO roofing is a single-ply thermoplastic membrane that has become a dominant force, capturing over 40% of the commercial roofing market. Engineered from polypropylene and rubber with a reinforced fabric core, it’s designed for low-slope and flat roofs. Its signature heat-welded seams create a seamless, durable barrier that outperforms traditional adhesive methods. For Pasadena property owners seeking a reliable solution, a professional Pasadena roofing contractor can attest to TPO’s proven blend of energy efficiency, durability, and cost-effectiveness.

Key Facts About White TPO Roofing:

- Material: Thermoplastic Polyolefin (TPO) with a reinforcing scrim

- Thicknesses: 45, 60, and 90 mil

- Cost: $3.00 to $9.00 per sq. ft. installed

- Lifespan: 15-25 years

- Primary Benefit: High solar reflectivity reduces cooling costs

- Installation: Heat-welded seams for a monolithic, watertight barrier

The bright white surface reflects sunlight instead of absorbing it, directly lowering air conditioning bills during brutal Texas summers. This material also resists mold, punctures, and chemical exposure while remaining flexible in extreme temperatures. From warehouses along the Ship Channel to retail centers in Clear Lake, white TPO roofing systems consistently deliver superior performance and measurable energy savings in our demanding Gulf Coast climate.

I’m Jason Roberts, owner of 12 Stones Roofing & Construction. For over a decade, I’ve overseen hundreds of TPO installations across the region. Our certified team specializes in commercial roofing systems built to withstand Texas heat, humidity, and severe weather.

What is TPO Roofing? A Closer Look at the Market Leader

Thermoplastic Polyolefin (TPO) is a single-ply roofing membrane, meaning it protects a building with one continuous, engineered sheet. This streamlined approach reduces installation time and labor costs, a significant advantage for property owners. At 12 Stones Roofing & Construction, we install white TPO roofing engineered for the specific demands of commercial and industrial buildings.

The membrane consists of a polypropylene and rubber polymer blend, reinforced with a fabric scrim. This internal scrim acts as a backbone, giving TPO impressive strength and flexibility to move with the building without tearing. This construction makes TPO highly resistant to punctures and impacts. Its bright white surface actively reflects solar radiation, a major cost-saver during hot Pasadena summers.

TPO is ideal for the large, flat, or low-slope roofs common on commercial buildings. Its heat-welded seams create a monolithic, watertight surface that protects your property for years. For more details on options in our area, see our comprehensive guide to commercial roofing in Pasadena.

TPO Membrane Types and Thicknesses

TPO membranes are not one-size-fits-all. The thickness, measured in mils (thousandths of an inch), impacts durability and budget.

- 45 mil TPO: The standard, cost-effective option suitable for buildings with minimal foot traffic, like warehouses or some retail centers.

- 60 mil TPO: The most popular choice, offering a great balance of cost and performance. Its improved puncture resistance makes it ideal for roofs with moderate foot traffic or rooftop HVAC units. We commonly recommend this for Pasadena businesses.

- 90 mil TPO: The heavy-duty option for maximum protection. It stands up to severe weather, heavy foot traffic, and demanding industrial use.

While thicker membranes are generally more durable, the manufacturer’s quality is paramount. A premium 60 mil membrane from a top-tier brand will often outperform a budget 90 mil product.

TPO is manufactured in wide rolls—typically 10, 12, and 20 feet—which means fewer seams are needed across the roof. According to the National Roofing Contractors Association (NRCA), fewer seams improve long-term performance by reducing potential points of failure. Wider sheets also allow for faster installation, minimizing downtime for your business.

The Best Advantages of a White TPO Roofing System

White TPO roofing delivers a powerful combination of features that protect your investment and improve your bottom line. Its advantages range from superior installation methods to significant energy savings.

The installation sets TPO apart. Seams are heat-welded with specialized equipment, fusing the membrane at a molecular level. This creates a bond stronger than the membrane itself, forming a continuous, watertight barrier that eliminates the weak points found in systems using adhesives or tapes. TPO’s flexibility allows it to expand and contract with temperature changes without cracking, and it naturally resists mold, punctures, and chemical exposure, reducing long-term maintenance costs.

Superior Energy Efficiency and Cost Savings

For Texas property owners, the financial benefit of white TPO roofing is a game-changer. The bright white surface acts as a shield against the sun, reflecting up to 80% of UV rays. This “cool roof effect” keeps the building’s interior cooler, so your air conditioning system runs less.

Dark roofs can reach 180°F, but a white TPO roof stays much closer to the ambient temperature. This drastically reduces heat absorption, leading to reported cooling cost reductions of 20-30%. These savings add up month after month. Most white TPO membranes are ENERGY STAR® certified and rated by the Cool Roof Rating Council, verifying their performance and making TPO a cornerstone of energy-efficient roofing in Houston.

Durability and Performance in Texas Weather

Texas weather is tough on roofs, but white TPO roofing is engineered to handle it. Its exceptional UV resistance prevents the material from becoming brittle under the relentless sun. The membrane’s composition also naturally resists fungal growth, a common issue in our humid climate.

Properly installed TPO systems achieve high wind ratings, crucial during tropical storms, as the heat-welded seams won’t peel up. While no roof is hail-proof, TPO’s reinforced flexibility helps it absorb impacts without puncturing. It also handles extreme temperature swings without developing stress cracks, ensuring its integrity year after year.

TPO vs. Other Single-Ply Membranes

When comparing single-ply options, TPO strikes an ideal balance for most Texas applications.

- vs. EPDM (Black Rubber): TPO’s heat-welded seams are stronger than EPDM’s taped or glued seams, which can degrade over time. Critically, standard black EPDM absorbs heat, increasing cooling costs, whereas white TPO reflects it.

- vs. PVC: Both TPO and PVC use strong, heat-welded seams. PVC offers superior resistance to grease and chemicals, making it ideal for restaurants, but it is typically more expensive. TPO provides excellent durability and chemical resistance for most other commercial applications at a more competitive price point.

As the National Roofing Contractors Association (NRCA) notes, material choice should match the climate. EPDM’s heat absorption is a liability in Texas, while PVC’s benefits may be overkill for a standard office or warehouse. White TPO roofing offers the best combination of welded seams, solar reflectivity, and durability for our region’s needs.

TPO Roof Installation: Process, Methods, and Costs

A proper white TPO roofing installation is a methodical process that ensures decades of protection. It requires skilled execution at every stage, from surface preparation to the final weld.

The process begins with preparing the substrate by cleaning the surface and ensuring it is smooth and free of debris. Next, insulation boards (typically Polyiso) are installed in a staggered pattern for thermal efficiency and structural integrity. The TPO membrane is then unrolled and allowed to relax to prevent wrinkles. Finally, using hot-air welders at 500-600°F, technicians overlap the TPO sheets and fuse them together, creating seams that are stronger than the membrane itself. This monolithic barrier is what makes TPO so effective against water intrusion.

Key Installation Methods Explained

There are three primary installation methods for white TPO roofing:

- Fully Adhered: The membrane is glued directly to the insulation board. This method provides a smooth finish and excellent wind uplift resistance, making it our most recommended option for coastal areas like Pasadena.

- Mechanically Attached: The membrane is secured with screws and plates hidden within the heat-welded seams. This is often a faster and more economical choice for large roof areas and offers great performance in high-wind zones when installed to specification.

- Ballasted: The membrane is laid loosely and held in place with a layer of river rock or pavers. This is a cost-effective method but adds significant weight, so the building’s structure must be able to support the load.

Regardless of the method, adhering to professional standards is critical for a successful project.

The Cost of a White TPO Roofing Installation

White TPO roofing systems typically cost between $3.00 and $9.00 per square foot installed, though market conditions can sometimes push this range to $6-$12. Several factors influence the final price:

- Roof Size & Complexity: Larger, simpler roofs have a lower cost per square foot than smaller, complex roofs with many penetrations (vents, skylights, etc.).

- Insulation: Higher R-value insulation costs more upfront but provides greater long-term energy savings.

- Membrane Thickness: A 45 mil membrane is the most affordable, while 60 mil and 90 mil options cost more but offer increased durability and longevity.

- Existing Roof Condition: A full tear-off of a damaged existing roof adds significant labor and disposal costs. If the roof is in good shape, a “recover” installation over the top can save money.

- Labor: Experienced, certified crews may cost more, but quality installation is the single most important factor in a roof’s long-term performance.

Lifespan, Maintenance, and Repair for Your TPO Roof

A professionally installed white TPO roofing system is built for the long haul, with a typical lifespan of 15 to 25 years. With proper care, some premium systems can last even longer. Longevity depends on installation quality, climate, maintenance frequency, and the manufacturer’s quality.

Essential TPO Roof Maintenance

Proactive maintenance is the key to maximizing your roof’s lifespan. A simple routine can prevent small issues from becoming costly problems.

- Inspect Regularly: Check the roof twice a year (spring and fall) and after major storms. Look for loose seams, punctures, or damaged flashing.

- Keep it Clean: While TPO resists dirt, a gentle wash annually helps maintain its reflectivity. Remove any accumulated leaves or debris.

- Check Seams and Flashings: Pay close attention to the areas around vents, pipes, and HVAC units, as these are common trouble spots.

- Ensure Proper Drainage: Keep gutters and drains clear to prevent water from pooling, which can stress seams and lead to damage.

Common Repairs and Warranty Options

Even durable roofs can need repairs, but TPO is generally easy to fix. Minor punctures are repaired by heat-welding a compatible TPO patch over the damaged area for a permanent, watertight seal. Failed seams can often be re-welded. While sealants can provide a temporary fix, a proper heat-welded repair is always the recommended permanent solution.

A major concern is insulation saturation. If an infrared inspection reveals widespread moisture (over 25% of the roof area), a full tear-off and replacement is usually necessary. For smaller wet areas, a spot repair is often possible.

When you invest in a TPO roof, you typically receive two warranties: a manufacturer warranty covering material defects (often 10-20 years) and a labor warranty from your installer covering workmanship. Choosing a certified contractor is crucial to ensure your warranties are valid and your investment is protected.

Frequently Asked Questions about White TPO Roofing

How does white TPO roofing perform in the hot Texas climate?

White TPO roofing is engineered to excel in hot climates like Texas. Its bright white surface reflects a high percentage of solar radiation, preventing heat absorption. This “cool roof” effect keeps the building cooler, significantly reducing the strain on air conditioning systems and lowering energy bills. Furthermore, TPO’s formulation includes strong UV inhibitors that prevent the material from cracking or degrading under the intense Texas sun, ensuring long-term performance.

What is the best thickness for a TPO roof?

The best thickness depends on your building’s use and budget. TPO is available in 45 mil, 60 mil, and 90 mil options.

- 45 mil is a cost-effective standard for buildings with minimal foot traffic.

- 60 mil is the most common choice, offering a balance of durability and cost for roofs with moderate traffic or rooftop equipment.

- 90 mil provides maximum durability and is ideal for high-traffic industrial facilities or areas prone to severe weather.

An experienced contractor can help you select the optimal thickness for your specific needs.

Can you install TPO over an existing roof?

Yes, installing TPO over an existing roof, known as a “re-cover,” is a cost-effective option if certain conditions are met. The existing roof must be structurally sound and have only one layer, as building codes typically limit roofs to two layers total.

Most importantly, the underlying structure must be dry. A thorough inspection, often using infrared scanning, is required to detect trapped moisture. If less than 25% of the insulation is wet, those areas can be replaced before the re-cover. If moisture is more widespread, a complete tear-off is the recommended long-term solution to prevent structural damage and mold.

Protect Your Pasadena Business with a Premier TPO Roof

For safeguarding your commercial property in Pasadena, white TPO roofing is a clear champion. It’s an investment in your business’s future, delivering exceptional energy savings, incredible long-term durability, and remarkable cost-effectiveness. Here at 12 Stones Roofing & Construction, we see how this material provides a robust shield against our challenging Texas weather. Its efficient installation and simple maintenance make it a smart choice for any local business owner.

We are more than just roofers; we are your neighbors, dedicated to delivering premier commercial roofing solutions in Pasadena. Our team brings deep local expertise, a firm commitment to safety, and transparent service to every project. We understand the demands of the Gulf Coast climate and install roofing systems that exceed expectations. Our dedication extends across the entire Houston metro area, ensuring businesses throughout the region receive the same high standard of care.

Ready to give your commercial property the protection it deserves? Partnering with experienced professionals is key. Explore our dedicated TPO roofing services to learn more, and request a detailed consultation from our team. Let’s protect your investment together.