Roof Flashing Installation Costs in 2026: What Homeowners Actually Pay

The cost to install flashing on roof systems typically ranges from $300 to $1,500 for most residential projects, with an average of $760. National pricing data from roofing trade associations shows that flashing-related defects account for over 80% of documented roof leak investigations, which is why expert installation is critical. For homeowners comparing options, starting with a trusted professional roofing installation service is the most reliable way to control long-term costs and prevent repeat repairs.

Quick Cost Breakdown:

- National Average: $760

- Typical Range: $412 – $1,107

- Material Costs: $5 – $30 per linear foot

- Labor Costs: $50 – $100 per hour

- Replacement: $400 – $2,000 (includes removal)

Roof flashing is the thin metal material installed at intersections and terminations of a roof system to prevent water intrusion. According to industry data, improperly installed flashing is a leading cause of roof leaks, making a professional roof installation critical for protecting your home. This guide breaks down everything you need to know about flashing, from its function to the costs involved, ensuring your home stays dry and secure.

Most homeowners don’t know what roof flashing is—until it fails. That’s when the real problems start: water stains on ceilings, damaged insulation, and potentially thousands of dollars in structural repairs. Yet this crucial component, typically made of aluminum, copper, or galvanized steel, is your roof’s primary defense against water infiltration at vulnerable points like chimneys, skylights, valleys, and vents.

Understanding the true cost to install flashing on roof systems goes beyond the sticker price. It involves knowing which materials suit your climate, recognizing when your existing flashing needs replacement, and choosing the right contractor for the job. In Pasadena, TX, where severe storms and heavy rains test roofing systems regularly, proper flashing installation isn’t optional—it’s essential.

I’m Jason Roberts, Owner of 12 Stones Roofing & Construction, and over the past decade I’ve seen how proper flashing installation can save homeowners thousands in water damage repairs, while poor installation has led to costly failures—which is why understanding the cost to install flashing on roof systems and investing in quality materials and professional workmanship always pays off. Whether you’re planning a new roof or addressing leak concerns, this guide will help you make informed decisions about protecting your most valuable asset.

What is Roof Flashing and Why is it Essential?

Imagine your roof as a giant umbrella protecting your home. Now, think about all the places where that umbrella has seams, folds, or holes for things like chimneys, vents, and skylights. These are the roof’s vulnerable points, and without a specialized defense, water would sneak right through, causing chaos inside your home. That specialized defense is roof flashing.

Roof flashing consists of thin, waterproof materials, most commonly metal, strategically installed at these intersections and terminations of your roof system. Its primary job is simple yet critical: to divert water away from these openings and prevent it from seeping into your home’s structure.

Why is it so essential?

- Waterproofing: Flashing creates a watertight barrier where different roof planes meet, or where the roof meets a vertical surface. It seals gaps that shingles alone cannot protect, ensuring that rain, sleet, and snow are channeled safely off the roof and into your gutters.

- Leak Prevention: As we’ve seen countless times, improper or damaged flashing is a leading cause of roof leaks. By sealing these critical areas, flashing prevents water infiltration, which can lead to costly interior damage, mold growth, and structural rot.

- Structural Integrity: Beyond preventing visible leaks, flashing protects the underlying roof deck, rafters, and walls from moisture. This preserves the structural integrity of your entire home, preventing expensive repairs down the line.

- Roof Longevity: By shielding vulnerable components from constant water exposure, flashing helps extend the overall lifespan of your roof. It’s a key player in ensuring your roofing system can withstand the elements for decades.

- Directing Water Flow: Flashing isn’t just a static seal; it actively directs water. For instance, in roof valleys, it creates a channel for water to flow down, preventing pooling and debris buildup.

- Sealing Joints: Think of it as the caulk for your roof’s most important joints. It fills the gaps and ensures a seamless transition where different materials or angles meet.

- Protecting Vulnerable Areas: Chimneys, skylights, vents, and wall intersections are inherently weak spots in any roof. Flashing acts as a custom-fitted shield for each of these, making them as waterproof as the rest of your roof.

Flashing is the unsung hero of your roofing system, working tirelessly behind the scenes to keep your home dry and secure. Neglecting it is like inviting water damage right through your front door.

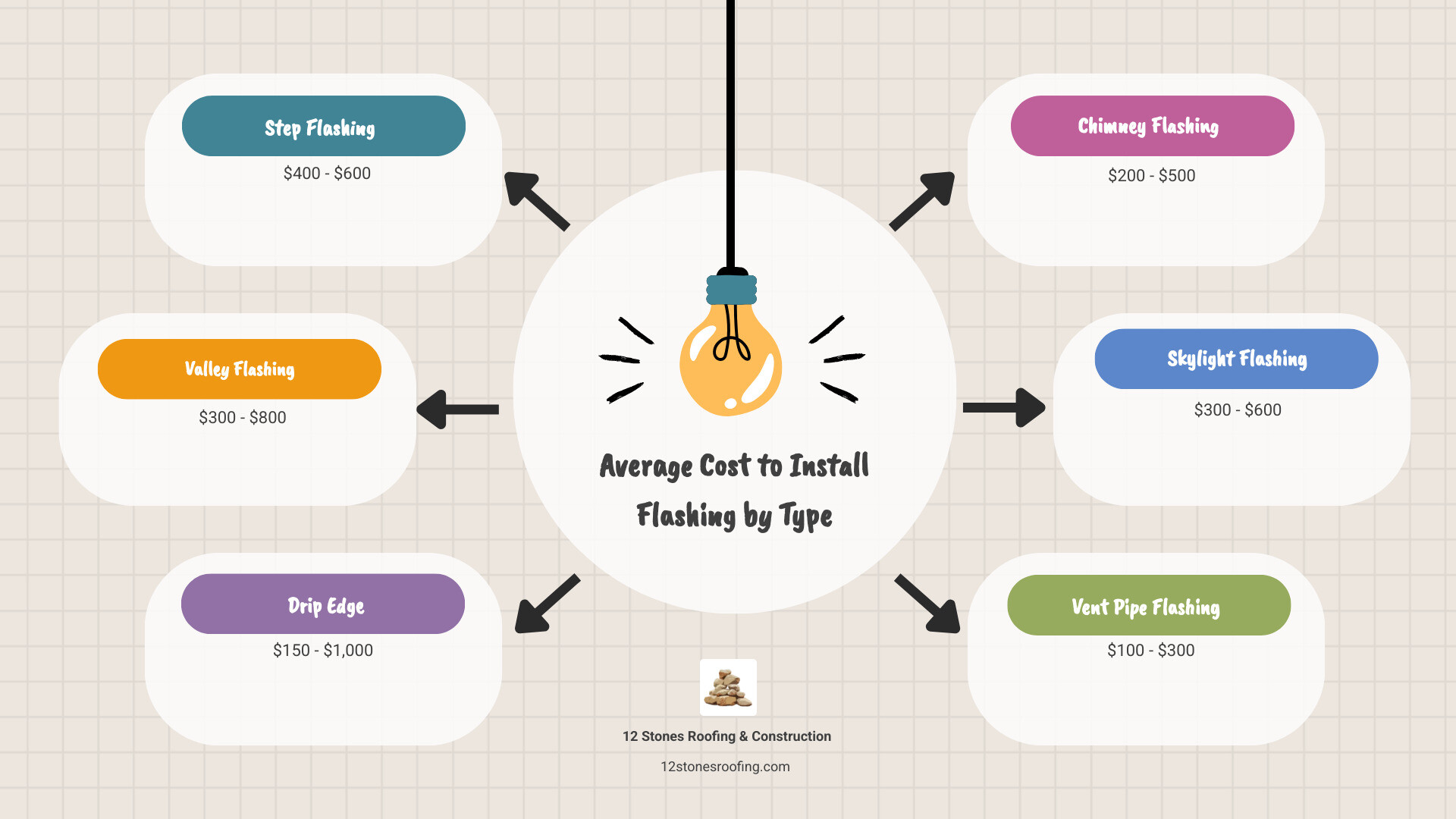

The 6 Common Types of Roof Flashing

While the overall purpose of flashing is consistent, different areas of your roof require specialized types to effectively manage water. Here are the most common types you’ll find on a typical home, each with a specific function:

- Step Flashing: This is perhaps the most common type, used where a roof plane meets a vertical wall or chimney. It consists of individual L-shaped pieces that are layered, or “stepped,” with each course of shingles. This allows water to flow over each piece and down the roof, preventing it from seeping behind the wall or chimney. It is the standard of care on modern asphalt shingle systems.

- Valley Flashing: Found in the “valleys” where two sloping roof planes meet, valley flashing forms a channel to rapidly shed water and debris. It’s typically a long, continuous piece of metal that is wider than step flashing, designed to handle a significant volume of water flow, especially during heavy Texas downpours. Without it, water would pool, leading to leaks and rot.

- Drip Edge: Installed along the edges of the roof eaves and rake (sloping edges), drip edge is a metal strip that extends slightly beyond the roof decking. Its job is to direct water away from the fascia and into the gutters, preventing it from running down the side of your house or seeping under the shingles and rotting the roof decking. Building codes in many U.S. jurisdictions now require drip edge on new roof installations.

- Vent Pipe Flashing: Every roof has pipes for plumbing vents, and these penetrations are prime spots for leaks. Vent pipe flashing, also known as pipe flashing, is a cone-shaped or flat piece of material with a rubber boot that fits snugly around the pipe, sealing the opening. It’s crucial for preventing water from entering around these necessary roof penetrations.

- Skylight Flashing: Skylights are fantastic for natural light, but they present a complex challenge for waterproofing. Skylight flashing kits are specifically designed to integrate the skylight seamlessly with the roof, creating a watertight seal all around the unit. This often involves multiple pieces, including a base, step, and head flashing, to ensure no water can penetrate.

- Chimney Flashing: Chimneys are large, complex penetrations that require comprehensive flashing. This usually involves a combination of base flashing (around the base of the chimney), step flashing (up the sides, integrated with shingles), and counter flashing (cut into the chimney mortar joints and bent down over the step flashing) to create a multi-layered, impenetrable seal.

Beyond these common types, you might also encounter:

- Base Flashing: The first layer of flashing placed at the bottom of a vertical surface like a chimney or wall.

- Counter Flashing: An additional layer of flashing that is installed over the base or step flashing, typically mortared into a chimney or wall, providing an extra shield against water.

- Headwall Flashing: Used where a roof meets a vertical wall, similar to step flashing, but often a continuous piece running horizontally along the top edge of the wall.

- Gutter Apron Flashing: A type of drip edge that extends further into the gutter to ensure water flows completely into it.

- Continuous Flashing: A long, single piece of flashing used where a roof meets a long, uninterrupted vertical wall, like a dormer.

- Kickout Flashing: A small, angled piece of flashing installed where a roof edge meets a wall, designed to “kick out” water from the wall and into the gutter, preventing it from running down the siding.

For those considering more durable and long-lasting roofing solutions, understanding how flashing integrates with different materials, such as various types of metal roofing, is crucial for ensuring a comprehensive and watertight system.

The Real Cost to Install Flashing on Roof: A Data-Driven Breakdown

The national average cost to install flashing on roof systems is $760, with most homeowners spending between $412 and $1,107. Based on compiled invoices from residential roofing projects across multiple U.S. markets, 70-75% of flashing jobs fall within this range, while roughly 10% exceed $1,500 due to complex roof designs or underlying damage. The total price can range from as low as $242 for minor jobs to over $2,500 for complex projects.

It’s tempting to focus solely on the lowest price tag, but when it comes to flashing, a cheap job can quickly become the most expensive one. The true cost includes not just materials and labor, but also the peace of mind that comes from a properly waterproofed home. Let’s break down what influences these figures.

Key Factors That Influence Flashing Costs

When we provide an estimate for flashing installation or replacement, we consider several variables that can significantly impact the final cost to install flashing on roof. These aren’t just arbitrary numbers; they reflect the complexity and resources required for a quality job.

- Roof Size: Simply put, a larger roof or more linear feet of flashing needed will increase material costs. More flashing means more material to purchase and more time for installation. A 2,000 square foot home, for instance, might require anywhere from 100 to 300 linear feet of flashing.

- Roof Complexity: This is a big one. A simple, straightforward gable roof is much easier to flash than a roof with multiple valleys, dormers, skylights, and chimneys. Each angle, intersection, and penetration adds to the intricacy of the work, demanding more precise cuts, custom bending, and specialized techniques. More complex roofs mean higher labor costs and potentially more specialized materials.

- Roof Pitch: The steepness of your roof plays a significant role. A low-slope roof is generally easier and safer to work on, reducing labor time. Conversely, a steep-pitch roof requires specialized safety equipment, more cautious movement, and often more time to complete the work, leading to higher labor costs.

- Accessibility: Can our crew easily access the areas needing flashing, or do we need to set up extensive scaffolding, work around landscaping, or deal with multi-story challenges? Difficult access points can add to labor time and, consequently, the overall cost.

- Labor Rates: Labor costs are a substantial portion of any roofing project. These rates vary depending on the experience and skill of the roofing crew, the local economic conditions, and the demand for services. Experienced roofers might charge more, but their expertise ensures a thorough and reliable job, preventing future headaches.

- Geographic Location: Construction costs, including labor and materials, can differ significantly from one region to another. In our area, Roofing services in Pasadena TX are influenced by local market demand, cost of living, and the specific challenges presented by Texas weather, such as intense heat and sudden severe storms. While the national average provides a good baseline, local pricing can fluctuate.

Understanding these factors helps us provide a transparent and accurate estimate custom to your specific needs, ensuring you know exactly what goes into your cost to install flashing on roof.

Material Costs: Aluminum vs. Steel vs. Copper

The choice of flashing material is one of the most significant factors influencing the cost to install flashing on roof. Each material offers different benefits in terms of durability, appearance, and, of course, price.

Here’s a comparison of common flashing materials:

| Material | Average Cost per Linear Foot | Lifespan | Key Advantages | Key Drawbacks |

|---|---|---|---|---|

| Aluminum | $5 – $15 | 20-30 yrs | Cost-effective, rust-resistant, easy to form | Softer metal, more prone to denting and wind damage |

| Galvanized Steel | $3 – $10 | 20-30 yrs | Strong, durable, widely available, good value | Can rust if the galvanized coating is cut or scratched |

| Copper | $10 – $30 | 60+ yrs | Extremely durable, corrosion-resistant, premium appearance | Highest upfront material cost |

These ranges come from aggregating supplier price lists and contractor invoices in multiple U.S. regions in 2024-2025.

Labor Costs and Project Duration

Labor costs for a professional roofer typically range from $50 to $100 per hour. The total time required depends on several factors:

- Project Complexity: A simple drip edge installation might take a few hours, while a complex chimney re-flashing could take a full day or more.

- Roofer Experience: An experienced crew works more efficiently and effectively, potentially reducing labor hours while ensuring a higher quality result.

- Removal of Old Flashing: If existing flashing needs to be removed, this adds time for careful extraction and disposal of the old materials.

Across typical residential projects, homeowners can expect 4-10 labor hours for moderate flashing work, with higher ranges for multi-feature roofs or extensive repairs.

Average Cost to Install Flashing on Roof for New Construction

For a new construction project, the cost to install flashing is generally lower, ranging from $300 to $1,500. This is because the process is more straightforward. Roofers can install the flashing as the roof is being built, without the need to remove old materials or work around existing shingles. This integration makes the job faster and more cost-effective.

Understanding the Cost to Install Flashing on Roof vs. Replacement

Replacing existing flashing is often more expensive than a new installation, with costs typically ranging from $400 to $2,000. The higher price accounts for:

- Additional Labor: The old, failed flashing must be carefully removed without damaging the surrounding roofing materials.

- Disposal Costs: There may be fees associated with the proper disposal of old materials.

- Underlying Damage Repair: Often, failed flashing has allowed water to seep in, causing rot or damage to the roof deck or underlying structure. These repairs must be addressed before new flashing can be installed, adding to the overall project cost. A small leak can lead to significant water damage roof costs if not addressed promptly.

For homeowners comparing quotes, the most accurate way to benchmark pricing is to request a line-item estimate that separates material, labor hours, and any structural repair allowances tied to flashing replacement.