Understanding EPDM Roofing: The Durable Solution for Low-Slope Buildings

EPDM roofing is a high-performance synthetic rubber membrane, formally known as Ethylene Propylene Diene Monomer, that provides a durable and long-lasting solution for low-slope and flat roofs. For property owners in Texas, finding a roofing material that can withstand intense heat, sudden storms, and temperature fluctuations is critical. As an experienced roofing contractor in Pasadena, TX, we’ve seen how EPDM’s unique properties make it a top choice for protecting both commercial and residential investments. This guide breaks down everything you need to know about this reliable material.

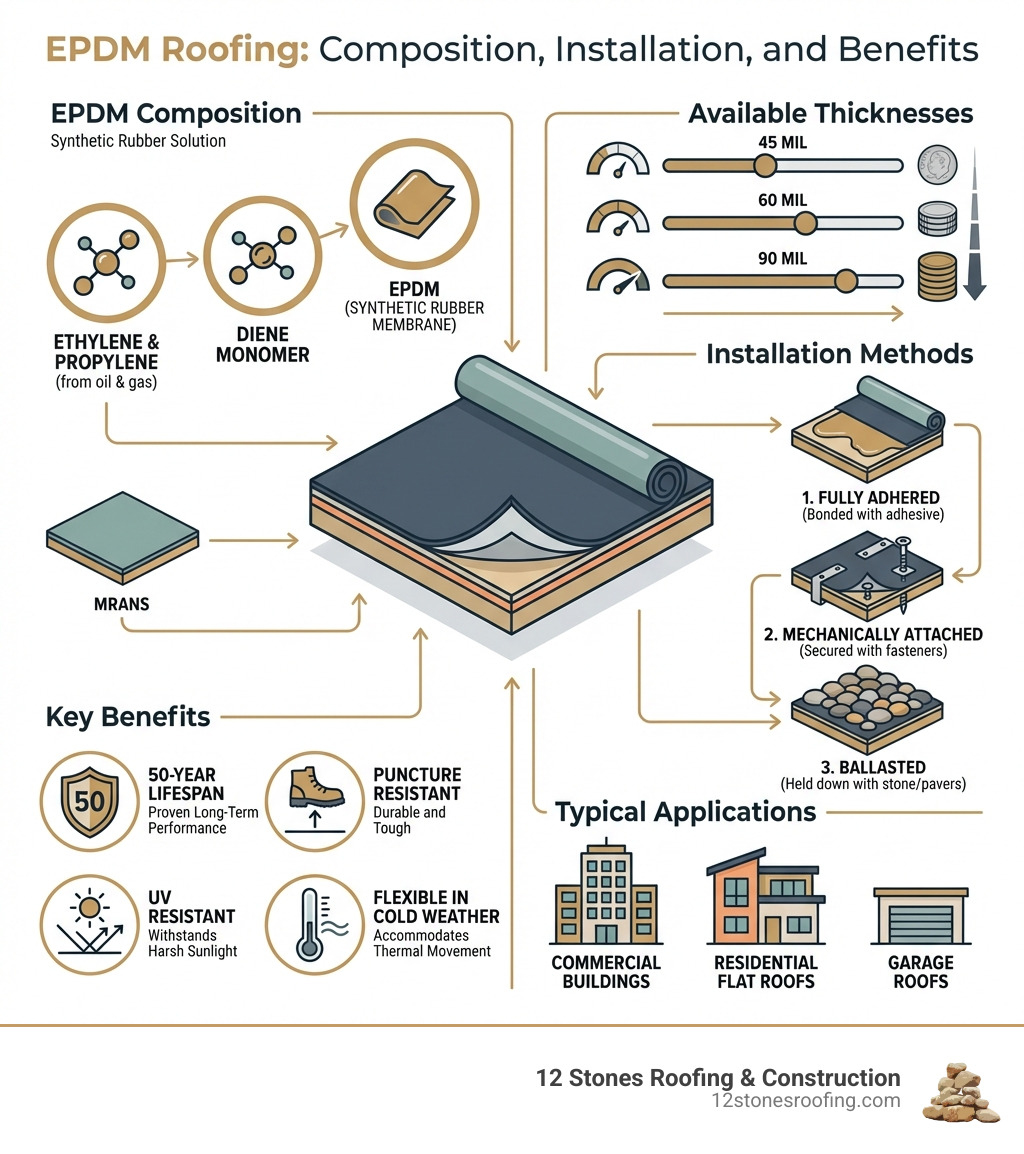

What is EPDM?

- Material: Ethylene Propylene Diene Monomer (synthetic rubber)

- Primary Ingredients: Ethylene and propylene derived from oil and natural gas

- Common Uses: Low-slope buildings, flat roofs, commercial structures

Key Specifications:

- Thicknesses Available: 45 mil (about the thickness of a dime), 60 mil, and 90 mil

- Sheet Sizes: Widths from 7.5 to 50 feet, lengths up to 100 feet

- Colors: Black, white, and gray

- Lifespan: Up to 50 years with minimal maintenance

Installation Methods:

- Fully adhered (bonded with adhesive)

- Mechanically attached (secured with fasteners)

- Ballasted (held down with stone or pavers)

If you’re dealing with an aging flat roof or storm damage, EPDM might be the solution you need. This proven material offers outstanding resistance to heat, ozone, and harsh weather while remaining one of the most cost-effective flat roofing options available. Whether you need a commercial roofing solution or a residential flat roof replacement, understanding EPDM’s benefits can help you make an informed decision.

Many times, a roof leak is detected from the inside of the property, and if caught early enough, can usually be isolated to one source on the roof. EPDM systems, when properly installed, are known for their watertight performance and rare leak occurrences. The material’s flexibility allows it to withstand building movement and extreme temperature fluctuations—critical factors in the Gulf Coast climate.

I’m Jason Roberts, owner of 12 Stones Roofing & Construction, and over the past decade I’ve overseen the installation of countless EPDM roofing systems across the Pasadena and Greater Houston area, helping property owners protect their investments with this reliable material. My hands-on experience with EPDM roofing in our challenging coastal climate has shown me why it remains a top choice for both commercial and residential flat roof applications.

Quick look at EPDM roofing:

What is EPDM Roofing? A Breakdown of the Basics

At its core, EPDM roofing is a high-performance synthetic rubber membrane, officially known as Ethylene Propylene Diene Monomer. It’s an incredibly versatile material, widely used on low-slope buildings and flat roofs across the United States and globally. We’ve seen its effectiveness in protecting countless properties in Pasadena, TX, from the relentless sun and sudden storms.

The Composition and Properties of EPDM

The primary ingredients of EPDM are ethylene and propylene, both derived from oil and natural gas. What makes EPDM so special is its unique polymer cross-linking during manufacturing. This process significantly improves its strength, durability, and most importantly, its elasticity. This elasticity means EPDM roofing can stretch and contract with temperature changes and building movement without cracking, which is a huge advantage in dynamic climates.

EPDM boasts outstanding resistance to deterioration from heat, ozone, and general weathering. Compared to many other roofing systems, it performs exceptionally well in cold weather, remaining flexible even in freezing temperatures. This flexibility is key to its longevity. Furthermore, EPDM typically has a perm rating of 1 or less, classifying it as a true moisture barrier, not just a retarder. This means it effectively stops water penetration, keeping your property dry and safe. For a deeper dive into what EPDM is, we recommend checking out resources like What is EPDM?.

Types, Thicknesses, and Colors of EPDM Roofing

One of the great things about EPDM roofing is the variety it offers to suit different project needs and budgets. You’ll primarily find it in three standard thicknesses:

- 45 mil: This is a common and cost-effective option, roughly the thickness of a dime. It’s suitable for many applications, especially residential flat roofs.

- 60 mil: Offering improved durability and puncture resistance, 60 mil EPDM is a popular choice for commercial properties and areas with moderate foot traffic.

- 90 mil: For the highest level of protection and longevity, 90 mil EPDM is ideal for demanding commercial environments or roofs that anticipate heavy foot traffic or equipment.

These membranes are available in impressive sizes, with widths ranging from 7.5 feet to a massive 50 feet, and lengths up to 100 feet. These large sheet sizes are a significant advantage, as they can minimize the number of seams required on a roof, reducing potential leak points.

When it comes to aesthetics and energy performance, EPDM offers a few color options:

- Black EPDM: This is the traditional and most common color. It’s excellent at absorbing heat, which can be beneficial in colder climates, helping to reduce heating costs.

- White EPDM: A fantastic choice for warmer climates like Pasadena. White EPDM is designed to reflect UV rays, significantly reducing heat absorption and lowering air conditioning costs.

- Gray EPDM: A less common but available option, offering a neutral aesthetic.

You can explore the various EPDM Membrane options to find the perfect fit for your project.

The Best Advantages of an EPDM System

When we recommend EPDM roofing, it’s because we’ve seen its real-world benefits time and again. This system offers a compelling combination of advantages that make it a smart investment for many property owners in Pasadena.

Superior Durability and Longevity

One of the most impressive aspects of EPDM roofing is its incredible durability and expected lifespan. With proper installation and minimal maintenance, an EPDM roof can last up to 50 years. That’s a half-century of protection for your property! This longevity translates into significant long-term savings by reducing the frequency of roof replacements.

Its inherent flexibility is crucial for its long life. EPDM remains pliable in cold temperatures, preventing cracking and brittleness that can plague other materials. It also boasts high resistance to UV radiation, a major factor in material degradation, especially under the intense Texas sun. Furthermore, EPDM offers excellent puncture and tear strength, standing up well to hail, debris, and occasional foot traffic. These Standard Attributes of EPDM contribute directly to its reputation as a robust and reliable roofing solution.

Energy Efficiency and Aesthetic Appeal

EPDM isn’t just tough; it can also be smart about energy. While black EPDM effectively absorbs heat, which can be advantageous in cooler climates by reducing heating bills, white EPDM shines in warmer regions like ours. White EPDM combines the high-performance standards of traditional EPDM with a highly reflective surface. This reflection of UV rays significantly reduces heat absorption, leading to lower interior temperatures and, consequently, reduced air conditioning costs. We’ve helped many clients in Pasadena reduce their energy consumption with white EPDM systems.

Beyond its functional benefits, EPDM also offers a clean and smooth surface, giving commercial buildings a professional and aesthetically pleasing look. Its flat, even surface also makes it an ideal base for rooftop gardens (also known as green roofs), which can further improve air quality and reduce carbon emissions. It’s also perfectly suited for integrating solar panels, allowing you to harness renewable energy while protecting your investment. We even saw a fascinating example where EPDM was used for solar power installations on telescopes in Hawaii, demonstrating its adaptability to challenging environments.

A Guide to EPDM Roofing Installation and Components

The installation of EPDM roofing is a specialized process that, when done correctly, ensures the system performs optimally for decades. Unlike some older roofing methods, EPDM installation is often a “cold-applied” process, meaning there’s no need for open flames. This makes the installation safer, typically odor-free, and often allows for year-round installation, as the material remains flexible even in cooler temperatures.

The Three Main Installation Methods

We employ three primary methods for installing EPDM roofing, each chosen based on the specific roof structure, local building codes, and project requirements:

- Fully Adhered Systems: This is often considered the preferred method, especially for larger roofs or those with many penetrations. The EPDM membrane is completely bonded to the substrate using a contact adhesive. This method creates a smooth, monolithic surface that offers excellent wind uplift resistance and a clean aesthetic. It’s a great choice for roofs that might experience high winds, like those we see in Pasadena.

- Mechanically Attached Systems: In this method, the EPDM membrane is secured to the roof deck using fasteners and plates. These fasteners are typically installed along the seams or in rows across the roof, with the next sheet then covering the fasteners. This can be a more cost-effective option for certain large, open roof areas and offers good wind uplift performance.

- Ballasted Systems: This is the simplest installation method. The EPDM membrane is loose-laid over the roof deck and then held in place by a layer of ballast, typically river-washed stone or concrete pavers. The ballast usually weighs between 10 to 12 pounds per square foot. This method is often the most economical and can offer additional insulation benefits. However, it requires a roof structure strong enough to support the extra weight and is not suitable for steeply sloped roofs or those with limited load-bearing capacity.

Essential EPDM Accessories and Seam Technology

The longevity and performance of an EPDM roofing system heavily rely on the quality of its components and the meticulous sealing of its seams. We use a range of specialized EPDM accessories and advanced seam technology to ensure a watertight and durable roof.

Here’s a list of crucial components:

- Seam Tapes: These specially formulated tapes are used to create robust, watertight bonds between EPDM sheets, effectively eliminating liquid adhesives in many seam applications.

- Liquid Adhesives: Used for fully adhering the membrane to the substrate and for flashing details where tape isn’t suitable.

- Primers: Essential for preparing EPDM surfaces before applying tapes and peel-and-stick products, ensuring a strong, lasting bond.

- Flashing for Penetrations: Specialized EPDM strips are used to seal around pipes, vents, skylights, and other roof penetrations, which are common points for leaks if not properly addressed.

- Pre-fabricated Pipe Boots: These pre-formed EPDM pieces fit snugly around pipes, making it easier and more reliable to seal these complex areas.

- Pourable Sealer Pockets: Used to seal clusters of small penetrations, providing a watertight encapsulation.

- Protective Walkpads: For areas with anticipated foot traffic (e.g., HVAC maintenance paths), these durable pads are installed over the EPDM to prevent abrasion and punctures.

- Termination Bars: Used to secure the edges of the EPDM membrane at vertical surfaces, ensuring a tight seal against walls and parapets.

The importance of proper seam sealing cannot be overstated. While EPDM sheets can be massive, most roofs will require some seams. Historically, seams were weak points, but with advancements in seam tapes and adhesives, and with skilled installation, they are now incredibly reliable. We focus on meticulous preparation, including cleaning and priming, to ensure every seam is watertight and durable. For more details on the materials we use, check out our insights on EPDM Rubber Roofing Materials.

Lifespan, Maintenance, and Preventing Common Failures

One of the standout features of EPDM roofing is its impressive lifespan and relatively low maintenance requirements. As we’ve mentioned, an EPDM roof can easily last between 30 to 50 years, making it an excellent long-term investment. Beyond its functional longevity, EPDM is also highly recyclable at the end of its life, contributing to a lower environmental impact over its entire lifecycle. This aligns with our commitment to offering sustainable roofing options where possible. Environmental Product Declarations (EPDs) are increasingly used to compare the environmental impact of building materials, and a new supplement offers a faster way to interpret this information, as highlighted by EPDs at a Glance.

Proactive EPDM Roof Maintenance

While EPDM roofing is known for being low-maintenance, “minimal” doesn’t mean “no” maintenance. A proactive approach can significantly extend its lifespan and prevent costly repairs down the line. We recommend the following:

- Regular Inspections: Schedule professional roof inspections at least twice a year, ideally in spring and fall, and especially after any major storms that hit our Pasadena area. This allows us to catch minor issues before they become major problems.

- Cleaning: Keep the roof surface clear of leaves, branches, and other debris. Accumulated organic matter can trap moisture and promote algae or moss growth, which can harbor moisture and slowly degrade the membrane.

- Seam and Flashing Checks: Pay close attention to all seams, flashing around penetrations, and edge terminations. Look for any signs of lifting, cracking, or deterioration. Early detection of seam issues is crucial.

- Addressing Ponding Water: While EPDM is waterproof, prolonged ponding water (water that remains on the roof for more than 48 hours) can stress seams and accelerate degradation. If you notice consistent ponding, it indicates a drainage issue that needs to be addressed.

- Prompt Repairs: Don’t delay addressing any detected damage. Even a small tear or lifted seam can lead to significant water intrusion. Our team is ready for roof repair for leaks to ensure your EPDM roof remains watertight.

Common Causes of EPDM Roof Failure

Even the toughest roofs can face challenges. Understanding the common causes of EPDM roof failure helps us prevent them during installation and address them quickly during maintenance.

- Membrane Shrinkage: Over time, particularly with older formulations, EPDM can experience some shrinkage. This can cause the membrane to pull away from parapet walls, stress seams, and create “tenting” at terminations or wrinkling around penetrations. Experienced installers will account for this by using excess material during installation.

- Seam Failure: This was historically a significant concern with EPDM. Adhesives can dry out and weaken over time, leading to seams separating. Improper cleaning, priming, or adhesive application during installation are also common culprits. Modern seam tapes and rigorous installation practices have dramatically improved seam integrity.

- Punctures: While durable, EPDM can still be punctured by sharp objects, falling debris, or excessive, unprotected foot traffic. This is why we recommend walkpads in high-traffic areas.

- Flashing Embrittlement: In older installations, uncured neoprene flashing sometimes used with EPDM could craze-crack over time, leading to leaks. Today, cured EPDM flashing is the standard, which is much more resilient.

- Fastener Back-out: In mechanically attached systems, fasteners can sometimes back out due to over-tightening during installation or repeated membrane billowing from wind uplift. Regular inspections can identify and rectify this.

- Chemical Damage: EPDM can be damaged by exposure to certain chemicals, particularly grease, animal fats, oils, and petroleum solvents. This is a common issue near kitchen exhaust vents or roof-mounted HVAC units that might leak fluids. If chemical exposure is unavoidable, alternative materials or protective measures may be necessary.

For property inspectors and owners, understanding these issues is vital. We often refer to comprehensive guides like Inspecting EPDM Roofs to ensure we’re looking for all potential vulnerabilities.

EPDM vs. Other Flat Roofing Materials

Choosing the right flat roofing material can feel like a complex decision, with many factors to weigh. While EPDM roofing is an excellent choice for many, it’s helpful to understand how it stacks up against other popular flat roofing options, such as TPO and Modified Bitumen. We always consider the overall performance, long-term cost-effectiveness, and suitability for the specific climate and building type in Pasadena when making recommendations.

| Material | Average Lifespan | Installation Method | Durability | Key Advantage |

|---|---|---|---|---|

| EPDM | 30-50 years | Fully Adhered, Mechanically Attached, Ballasted | Excellent flexibility, UV resistance, cold weather performance, puncture resistance | Longest lifespan, cost-effective, easy repair |

| TPO | 20-30 years | Mechanically Attached, Fully Adhered (heat-welded seams) | Good puncture resistance, excellent reflectivity, UV resistance | Highly reflective (energy efficiency), strong seams |

| Modified Bitumen | 15-25 years | Torch-Applied, Cold-Applied, Self-Adhered | Good puncture resistance, multiple layers (redundancy) | Durable, good for high traffic, good waterproofing |

EPDM vs. TPO Roofing

EPDM and TPO (Thermoplastic Polyolefin) are both single-ply membranes, but they have distinct differences.

- Seam Technology: EPDM typically uses adhesive-based tapes for seams, which are highly effective when installed correctly. TPO, on the other hand, uses heat-welded seams, creating a monolithic, incredibly strong bond.

- Puncture Resistance: Both offer good puncture resistance, but thicker EPDM often has a slight edge in this regard due to its rubbery nature.

- Flexibility in Cold Weather: EPDM is renowned for its flexibility in cold temperatures, maintaining its elasticity without becoming brittle. TPO can sometimes stiffen in extreme cold, making EPDM a more reliable choice in climates with significant temperature swings.

- UV Resistance: Both materials offer excellent UV resistance. However, white TPO is generally more reflective than white EPDM, making it a top choice for extreme energy efficiency needs, especially in very hot, sunny climates.

- Cost: EPDM is often slightly more cost-effective upfront than TPO, though both are competitive.

For a deeper look into TPO, you can visit our page on TPO roofing.

EPDM vs. Modified Bitumen

Modified Bitumen (Mod-Bit) is a type of asphalt-based roofing system, typically installed in multiple layers.

- Installation Methods: EPDM is a single-ply system installed cold (adhered, mechanically fastened, or ballasted). Modified Bitumen often involves torch-applied installation, which uses an open flame (though cold-applied and self-adhered options exist). The cold-applied nature of EPDM can be a safer and less disruptive installation process.

- System Weight: Mod-Bit is generally heavier due to its multi-layered composition, which can be a consideration for roof deck load capacity. EPDM is lightweight, making it suitable for a wider range of structures.

- Number of Seams: As a single-ply system available in large sheets, EPDM typically has fewer seams than a multi-layered Mod-Bit system. Fewer seams generally mean fewer potential leak points.

- Repairability: Both are highly repairable. EPDM repairs are often straightforward with patches and adhesives, while Mod-Bit repairs involve similar material applications.

- Lifespan: EPDM generally boasts a longer lifespan (30-50 years) compared to Modified Bitumen (15-25 years).

You can learn more about this traditional flat roofing material on our page about Modified Bitumen roofing.

Frequently Asked Questions about EPDM Roofing

We often get questions about EPDM roofing from property owners in Pasadena. Here are some of the most common ones we encounter:

Can you walk on an EPDM roof?

Yes, you absolutely can walk on an EPDM roof. It is a durable material designed to withstand foot traffic, especially the thicker 60 mil and 90 mil membranes. However, for areas with regular maintenance traffic, such as around HVAC units or access points, installing designated walkpads is highly recommended. These pads provide an extra layer of protection, preventing abrasion and punctures from tools or repeated footsteps, extending the roof’s lifespan and maintaining its warranty.

Is EPDM a good choice for residential flat roofs?

Absolutely. EPDM is an excellent and common choice for residential properties with low-slope or flat sections, such as garages, porches, home additions, and even entire flat-roofed homes. Its durability, cost-effectiveness, and ease of maintenance make it a popular option for residential roofing projects. It provides reliable, watertight protection, which is crucial for preventing leaks and protecting your home’s interior. We’ve installed many EPDM roofs on residential properties right here in Pasadena.

How much does an EPDM roof cost?

The cost of an EPDM roof can vary significantly based on several factors. These include the membrane thickness (45, 60, or 90 mil), the chosen installation method (fully adhered, mechanically attached, or ballasted), the complexity of the roof’s design (e.g., number of penetrations, size, shape), and local labor rates in the Pasadena area. Generally, EPDM is considered one of the most cost-effective flat roofing options available, offering a strong balance between initial investment and long-term performance. For an accurate estimate custom to your specific property, we always recommend a professional inspection and quote.

Conclusion: Is EPDM the Right Choice for Your Property?

EPDM roofing has proven itself as a premier choice for protecting properties, offering an best combination of durability, longevity, and value. Its flexibility, resistance to the elements, and relatively simple installation make it ideal for a vast range of commercial roofing and residential applications. EPDM’s ability to withstand extreme temperatures, resist UV degradation, and provide a watertight barrier for decades makes it a truly reliable solution. From energy efficiency benefits with white membranes to its low maintenance profile and recyclability, EPDM stands out as a responsible and high-performing roofing material. If you need a reliable, low-maintenance system that can last for decades, EPDM is a top contender.

For expert advice and professional installation of EPDM roofing in the Pasadena area, trust the experienced team at 12 Stones Roofing & Construction. We understand the unique challenges our local climate presents and are dedicated to providing you with a roofing solution that protects your investment for years to come. To learn more about our services in the area, visit our Pasadena roofers page.

Ready to secure your property with a high-performance roof? Schedule your free EPDM roof inspection today.