The High Cost of Neglect: Why Rubber Roof Repair in Pasadena, TX Can’t Wait

For commercial properties in Texas, a durable roof isn’t a luxury—it’s a necessity. The relentless sun, sudden downpours, and high humidity in Pasadena put immense stress on roofing systems. While EPDM rubber roofs are known for their longevity, they aren’t immune to these challenges. Neglecting minor issues can lead to significant water intrusion, structural damage, and costly operational disruptions. Understanding the need for timely rubber roof repair pasadena tx is the first step in protecting your investment. Our specialized EPDM roofing services are designed to address these specific climate-related threats, ensuring your property remains secure and dry.

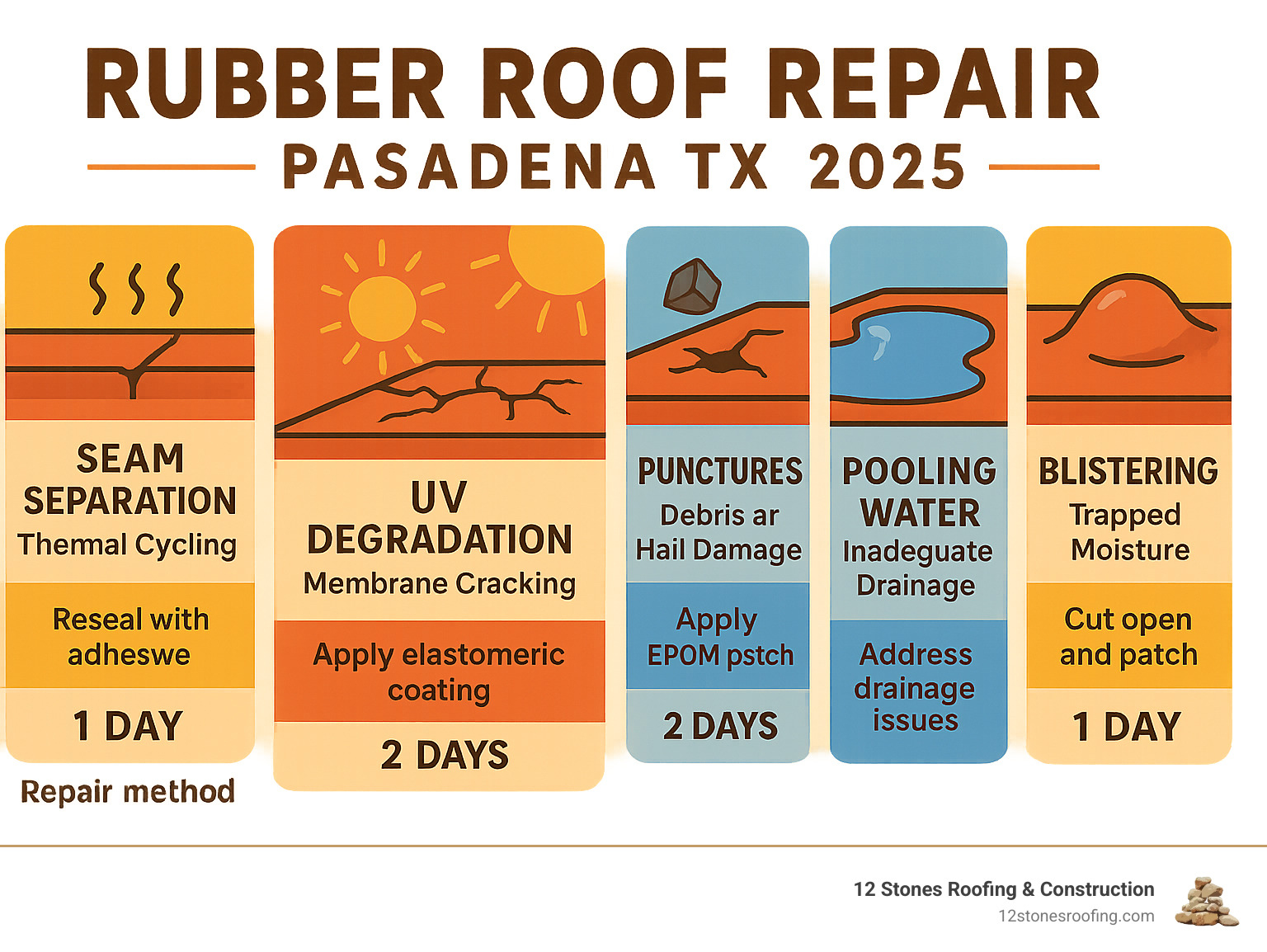

Quick Solutions for Common Rubber Roof Issues:

- Punctures & Tears: Clean area, apply EPDM patch with bonding adhesive

- Seam Separation: Reseal with adhesive or heat-weld new membrane sections

- Pooling Water: Address drainage issues and inspect for membrane damage

- UV Degradation: Apply reflective elastomeric coating for protection

- Blisters: Cut open, dry thoroughly, then patch damaged area

According to industry data, shrinkage, seam separation, and improper installation are the three most common types of EPDM failure. Regular inspections at minimum annually are recommended, though semi-annual checks provide better protection against Texas weather extremes.

The weather in Pasadena and the greater Houston area can be particularly unforgiving, causing storm damage that requires immediate attention. Small fissures in the rubber membrane can indicate potential leaks, while pooling water suggests drainage issues that degrade roof materials over time. Quality repairs protect against water damage, mold growth, and structural problems that cost far more than timely maintenance.

I’m Jason Roberts, owner of 12 Stones Roofing & Construction, and I’ve spent over a decade specializing in rubber roof repair pasadena tx for commercial properties throughout the Gulf Coast region. My team’s expertise with EPDM, TPO, and modified bitumen systems ensures your roof receives the professional care it deserves. Learn more about our local services at 12 Stones Roofing & Construction Pasadena.

Decoding the Distress Signals: When Your Rubber Roof Needs Repair

Pasadena’s climate can be brutal on commercial roofing systems. One day it’s blazing hot, the next you’re dealing with torrential downpours or even hail. While EPDM rubber roofs are built tough, they’re not invincible against our Texas weather extremes.

The key to protecting your investment? Catching problems early. When you know what warning signs to look for, you can prevent minor issues from turning into major headaches that threaten your entire building structure.

Pasadena’s weather creates specific challenges for rubber roofs. The constant temperature swings cause thermal cycling—your roof expands and contracts repeatedly, which wears down the material over time. Add in our intense UV rays, high humidity, and sudden storm systems, and you’ve got a recipe for accelerated roof aging.

Here are the clear warning signs that your roof is crying out for professional rubber roof repair Pasadena TX services:

Visible Cracks, Tears, and Punctures

Think of your rubber roof as your building’s protective armor. Even the smallest chink in that armor can spell trouble.

Small fissures and holes might look harmless, but they’re actually direct highways for water infiltration. These openings often result from foot traffic during maintenance, storm debris impact, or hail damage. What starts as a tiny puncture can quickly escalate into significant water damage affecting your insulation, roof deck, and building structure.

Don’t underestimate these seemingly minor flaws. A small tear today can become a major leak tomorrow, leading to expensive interior damage, compromised insulation, and potential mold growth throughout your building.

Seam Separation and Membrane Shrinkage

If your rubber roof has an Achilles’ heel, it’s the seams. These connection points bear the brunt of weather stress and are often the first to fail.

Seam separation happens when the adhesives holding membrane sections together begin to fail. Our Texas temperature extremes cause the rubber to expand and contract repeatedly, eventually breaking down these crucial bonds. You might notice the membrane pulling away from edges, vents, or flashing—creating gaps that invite water infiltration.

Membrane shrinkage is another common culprit. As the rubber ages and weathers, it can actually contract, creating openings around roof penetrations and perimeter areas. These gaps might start small, but they grow larger over time, creating hidden pathways for leaks that can cause extensive damage before you even notice them.

Pooling Water and Drainage Issues

Standing water on your roof 48 hours after rainfall is a red flag that demands immediate attention.

Pooling water accelerates roof deterioration in multiple ways. The constant moisture softens the rubber membrane, making it more vulnerable to punctures and tears. This standing water also adds significant weight stress to your building’s structural components, potentially causing sagging or other structural issues.

Beyond the immediate damage, stagnant water creates the perfect environment for algae and mold growth, which further degrades your roofing materials. Poor drainage doesn’t just signal a current problem—it’s actively making your roof’s condition worse every day it goes unaddressed.

Learn more about our Pasadena, TX roofing services

A How-To Guide: Proven Methods for EPDM Roof Repair

Once damage is identified, prompt and proper repair is crucial for maintaining your roof’s integrity. While some minor fixes may seem simple, rubber roof repair pasadena tx requires using the right materials and techniques for a long-lasting solution that stands up to our challenging climate. Here are the professional methods for addressing the most common rubber roof problems.

Think of EPDM repair like performing surgery—precision and the right tools make all the difference. Professional contractors rely on specialized materials including EPDM cleaner for surface preparation, patching kits designed specifically for rubber membranes, liquid sealant for watertight bonds, and heat-welding tools for seamless repairs. For extensive UV damage, reflective coatings provide both protection and energy savings.

Understanding EPDM’s unique properties is essential for effective repairs. This synthetic rubber material expands and contracts with temperature changes, which means repairs must be flexible enough to move with the membrane.

Fixing Punctures and Small Tears

Repairing punctures and small tears is like applying a medical bandage—it needs to be clean, precise, and properly sealed. The process begins with thorough cleaning using specialized EPDM cleaner to remove dirt, debris, and oils that could prevent proper adhesion. Even a tiny bit of contamination can cause the repair to fail down the road.

Next comes the patching process. A professional cuts the patch larger than the damaged area with rounded corners to prevent lifting—sharp corners are notorious for peeling up over time. The patch gets applied using a strong bonding adhesive specifically formulated for EPDM membranes. After firmly pressing the patch into place to ensure complete contact, the edges receive a final seal with lap sealant.

This multi-step approach creates a permanent, watertight bond that can withstand Pasadena’s temperature swings and storm conditions. It’s not just a quick fix—it’s a durable solution that becomes part of your roof system.

Addressing Separated Seams and Shrinkage

Seam repairs require a detective’s eye and a surgeon’s precision. For minor seam separation, professionals carefully clean the affected area and apply fresh seam adhesive or specialized tape. This re-establishes the critical bond that keeps water out of your building.

However, larger gaps or significant shrinkage around flashing calls for more extensive work. The old, compromised material may need complete removal before installing a new membrane piece. Here’s where the magic of heat-welding comes in—this technique creates a truly seamless bond that’s actually stronger than the original material.

Heat-welding essentially melts the EPDM materials together, creating what’s called a “monolithic surface.” It’s like the roofing equivalent of welding metal—when done properly, the repair becomes the strongest part of your roof.

Combating Blisters and UV Degradation

Blisters on your roof are like blisters on your feet—they need to be addressed before they burst and cause bigger problems. These unsightly bubbles form when air or moisture gets trapped under the membrane, often due to poor installation or substrate issues.

A professional tackles blisters by carefully cutting them open to release the trapped air or moisture, then allowing the area to dry completely. Once dry, the area gets patched using the same meticulous process as puncture repairs. Patience is key here—rushing this process leads to recurring problems.

To prevent future UV damage and extend your roof’s life, applying a reflective elastomeric coating is one of the smartest investments you can make. These bright white coatings act like sunscreen for your roof, bouncing harmful UV rays away and preventing the rubber from becoming brittle and cracking.

The bonus? These reflective coatings can significantly lower your energy costs by keeping your building cooler during Pasadena’s scorching summers. It’s a win-win situation where protecting your roof also protects your wallet.

The Smart Investment: Professional Rubber Roof Repair Pasadena TX

While DIY solutions may seem tempting, rubber roof repair pasadena tx requires specialized knowledge and tools to ensure lasting results. Hiring a professional roofing contractor in Pasadena is an investment in quality, safety, and peace of mind—protecting you from future headaches and expenses.

When it comes to professional rubber roof repair, we’re not talking about a quick YouTube tutorial and a trip to the hardware store. Professional repair means a comprehensive approach that starts with a thorough inspection, moves to proper diagnosis, and uses industry-standard materials and techniques that actually work in Texas heat and humidity.

Here’s what makes the professional difference: understanding local building codes and regulations, ensuring your repairs are compliant and safe. Plus, there’s something beautiful about a workmanship warranty from a reputable contractor—it’s like having a safety net that guarantees the work will hold up when the next storm rolls through.

Cost vs. Value: What to Expect for Pasadena Rubber Roof Repair

Let’s talk dollars and sense, because nobody likes financial surprises. Repair costs vary based on the extent of damage, the type of repair needed, and job complexity. But here’s the good news: in almost all cases, repairing a rubber roof costs significantly less than full replacement.

A professional quote breaks down materials, labor, and job complexity transparently—no hidden fees or surprise charges. While it might feel like an upfront investment, quality repair prevents those annoying recurring issues that keep eating into your budget. Think of it as preventative medicine for your roof. A small investment now can save you from that sinking feeling when you find water damage spreading through your building.

The long-term value is where professional repair really shines. Quality repairs extend your roof’s lifespan and protect against more expensive structural problems down the road. It’s the difference between a band-aid fix that fails in six months and a solution that lasts for years.

Repair or Replace? Making the Right Call

This is the thousand-dollar question that keeps property owners up at night. The decision between repair and replacement depends on several key factors, and getting it wrong can be costly.

If your roof is under 15 years old and damage is localized to specific areas, repairs are usually the smart, cost-effective choice. EPDM roofs are built to last 20-30 years with proper maintenance, so a young roof with minor issues has plenty of life left.

However, for older roofs (15-20+ years) showing widespread problems—multiple recurring leaks, extensive membrane deterioration, or significant shrinkage—replacement becomes the wiser long-term investment. It’s like that old car analogy: at some point, you’re throwing good money after bad.

| Criteria | Roof Repair | Roof Replacement |

|---|---|---|

| Damage Type | Localized damage | Widespread damage |

| Roof Age | Roof under 15 years old | Roof over 15-20 years old |

| Cost-Effectiveness | Cost-effective for minor issues | Multiple previous repairs |

Insurance claims can also factor into this decision. Storm-related damage often qualifies for coverage, whether you’re repairing or replacing. A professional contractor can help steer the insurance process and document damage properly for your claim.

Your Local Pasadena Roofing Experts

When you need reliable rubber roof repair pasadena tx, trust a team that understands the unique challenges of our local climate. We know what Gulf Coast weather can dish out, and we’re right here in your neighborhood, ready to respond quickly when you need us most.

12 Stones Roofing & Construction

Address: 6933 Olson Ln, Pasadena, TX 77505

Phone: (832) 815-9463

Proactive Care: A Maintenance Plan for Your EPDM Roof

The best way to avoid costly repairs is through a consistent preventative maintenance plan. Think of it like taking your car in for regular oil changes—a little attention now saves you from big problems later. Proactive care can dramatically extend the lifespan of your commercial rubber roof, ensuring it performs optimally for decades, even when Pasadena’s weather throws everything it has at you.

Regular maintenance isn’t just about saving money (though it definitely does that). It’s about peace of mind. When you know your roof is being properly cared for, you can focus on running your business instead of worrying about the next storm. We’ve put together a comprehensive Roof Maintenance Checklist to help you stay organized and ensure nothing gets overlooked.

Essential Maintenance Tasks

Semi-annual inspections are the cornerstone of any good maintenance plan. Having a professional inspect your roof every spring and fall might seem like overkill, but trust me—it’s not. These routine check-ups allow us to catch potential issues early, before they turn into expensive emergencies. Small fissures in the rubber membrane can indicate potential leaks, and early detection is your best defense against water damage.

Keeping your roof clean might sound obvious, but you’d be surprised how many property owners overlook this simple step. Regularly removing leaves, branches, and debris prevents them from clogging drains and gutters. When debris blocks drainage, you get pooling water, which as we’ve discussed, accelerates membrane deterioration and can lead to serious structural problems.

Tree trimming is another critical task that often gets forgotten until it’s too late. Those beautiful oak trees that provide shade for your building? They can become your roof’s worst enemy during a storm. Overhanging limbs can scrape against the roof surface during windy weather, causing abrasions that weaken the membrane. Even worse, they can break off and puncture your roof during severe weather events.

Protective coating maintenance is where prevention really pays off. If your rubber roof has a reflective coating, make sure it’s reapplied according to the manufacturer’s recommendations. These coatings are like sunscreen for your roof—they protect against UV degradation while reflecting heat away from your building. This double benefit means lower energy costs and a longer-lasting roof. It’s one of those win-win situations that make property maintenance actually feel good.

The key to successful rubber roof repair pasadena tx maintenance is consistency. Don’t wait for problems to find you—go looking for them first, when they’re still small and manageable. A well-maintained EPDM roof can easily last 25-30 years, but only if you give it the attention it deserves.

Secure Your Investment with Expert Rubber Roof Repair

Your commercial roof stands as your property’s first line of defense against Texas weather. Think of it as the guardian of everything underneath – your equipment, inventory, employees, and bottom line. When that guardian shows signs of wear, every day you wait is a gamble with potentially devastating consequences.

Don’t let minor leaks turn into major disasters that could shut down your business operations. A small puncture today can become a collapsed ceiling tomorrow, turning what might have been a simple repair into a complete interior renovation nightmare. The peace of mind that comes from addressing issues early is worth its weight in gold.

By understanding the warning signs of damage, proper repair methods, and the critical importance of preventative maintenance, you’re taking control of your investment. You’re not just fixing problems – you’re preventing future headaches and protecting your property value.

Knowledge is power, and now you have the tools to make informed decisions about your roof’s health. Whether it’s recognizing pooling water, spotting seam separation, or knowing when to call in the professionals, you’re equipped to be proactive rather than reactive.

When you need rubber roof repair pasadena tx services that are truly customized to our challenging local climate, trust the certified team at 12 Stones Roofing & Construction. We understand that every day of downtime costs you money, which is why we respond quickly and work efficiently to get your roof back to peak performance.

Our local expertise means we’ve seen every type of damage that Pasadena’s weather can dish out. We know how thermal cycling affects seam integrity, how UV exposure degrades membranes, and how our sudden storms can turn minor issues into major problems overnight. This isn’t just theoretical knowledge – it’s real-world experience gained from years of protecting commercial properties just like yours.

We’re here to ensure your roof stands strong for years to come, giving you one less thing to worry about so you can focus on running your business. Your success is our success, and it all starts with a roof that works as hard as you do.