Why Slate Look Concrete is Changing Outdoor Spaces

Slate look concrete is a decorative concrete method that uses specialized stamps to replicate the natural appearance of slate stone. This technique delivers the sophisticated aesthetic of natural slate at a fraction of the cost, with superior durability and faster installation. For property owners in Pasadena, TX, slate look concrete offers exceptional value, improving curb appeal and increasing property value. It perfectly complements the high-quality exterior improvements provided by 12 Stones Roofing & Construction, creating cohesive and durable outdoor living spaces.

Quick Answer: Creating Slate Look Concrete

- Prepare the surface – Excavate, compact sub-base, and install forms.

- Pour and level the concrete mix to the desired thickness.

- Apply color using integral color, color hardener, or both.

- Broadcast release agent to prevent stamps from sticking.

- Stamp the pattern while the concrete is still workable.

- Detail and cut joints for a refined look and crack prevention.

- Wash and cure for 24-48 hours.

- Seal the surface with two coats of a high-quality concrete sealer.

The timeless appeal of natural slate is undeniable, but its high cost and fragile nature have made it impractical for many. Stamped concrete eliminates these limitations. Industry data shows stamped concrete requires fewer workers and fewer hours to complete a project, making it substantially less expensive than natural slate. The longevity and durability of decorative concrete are also superior when compared to asphalt, natural rock, and pavers, making it a smart investment for withstanding the Texas climate.

What is Slate Look Concrete and Why is it So Popular?

Slate look concrete is a decorative technique that transforms ordinary concrete into a stunning replica of natural slate. The process uses detailed stamps to imprint realistic slate patterns onto freshly poured concrete, capturing the character of authentic stone without the fragility or high price.

Homeowners in Pasadena and throughout Texas are choosing slate look concrete for its ideal blend of aesthetics, durability, and cost-effectiveness. It provides the look of hand-selected stone without the risk of cracked tiles or weeds growing through gaps. The installation is remarkably efficient; stamping a large concrete surface is much faster and requires fewer workers than laying individual slate pieces, translating directly into significant cost savings.

The Unbeatable Advantages

Choosing slate look concrete offers more than just a pretty surface, especially in the demanding Texas climate.

- Aesthetic Versatility: With numerous patterns and a wide spectrum of colors, the look can be customized to match any home’s architectural style, from modern to traditional.

- Durability and Strength: As a solid, reinforced concrete slab, it can handle heavy foot traffic, patio furniture, and even vehicles without the chipping or cracking common with natural slate.

- Weather Resistance: A properly sealed stamped concrete surface resists fading, cracking, and erosion from Texas’s intense sun, humidity, and heavy rains far better than pavers or asphalt.

- Low Maintenance: The seamless surface eliminates the constant weeding and re-sanding required for pavers. Routine cleaning and resealing every few years are all that’s needed.

Durability: Stamped Concrete vs. Natural Materials

When investing in an outdoor space, longevity is key. Here’s how slate look concrete compares to other popular materials.

| Feature | Slate Look Concrete | Natural Slate | Pavers |

|---|---|---|---|

| Lifespan | 25+ years (with proper maintenance) | 20-50 years (as flooring/pavers), 75-150 years (roofing) | 15-25 years |

| Resistance to Weeds | Excellent (seamless surface) | Moderate (grout lines can allow growth) | Low (weeds common in joints) |

| Color Retention | Excellent (sealed, integral color) | Good (natural, but can fade/weather) | Moderate (can fade, susceptible to efflorescence) |

| Repair Difficulty | Moderate (sections can be cut/repaired) | High (matching individual pieces can be challenging) | Moderate (individual pieces can be replaced) |

While natural slate is durable, individual pieces are prone to chipping and can be difficult to replace. Pavers often require constant maintenance to combat weeds and settling. Slate look concrete sidesteps these issues, offering the sophisticated look of stone with the practical, long-lasting benefits of modern concrete technology.

Your Toolkit and Palette: Preparing for Your Project

Achieving a professional slate look concrete finish requires the right tools and materials. Understanding each component’s role is key to a successful project that captures a high-end stone appearance.

Essential Tools and Materials for Slate Look Concrete

- High-Quality Concrete Mix: A mix designed for workability and strength is essential.

- Formwork: Creates the crisp boundaries for your patio, walkway, or driveway.

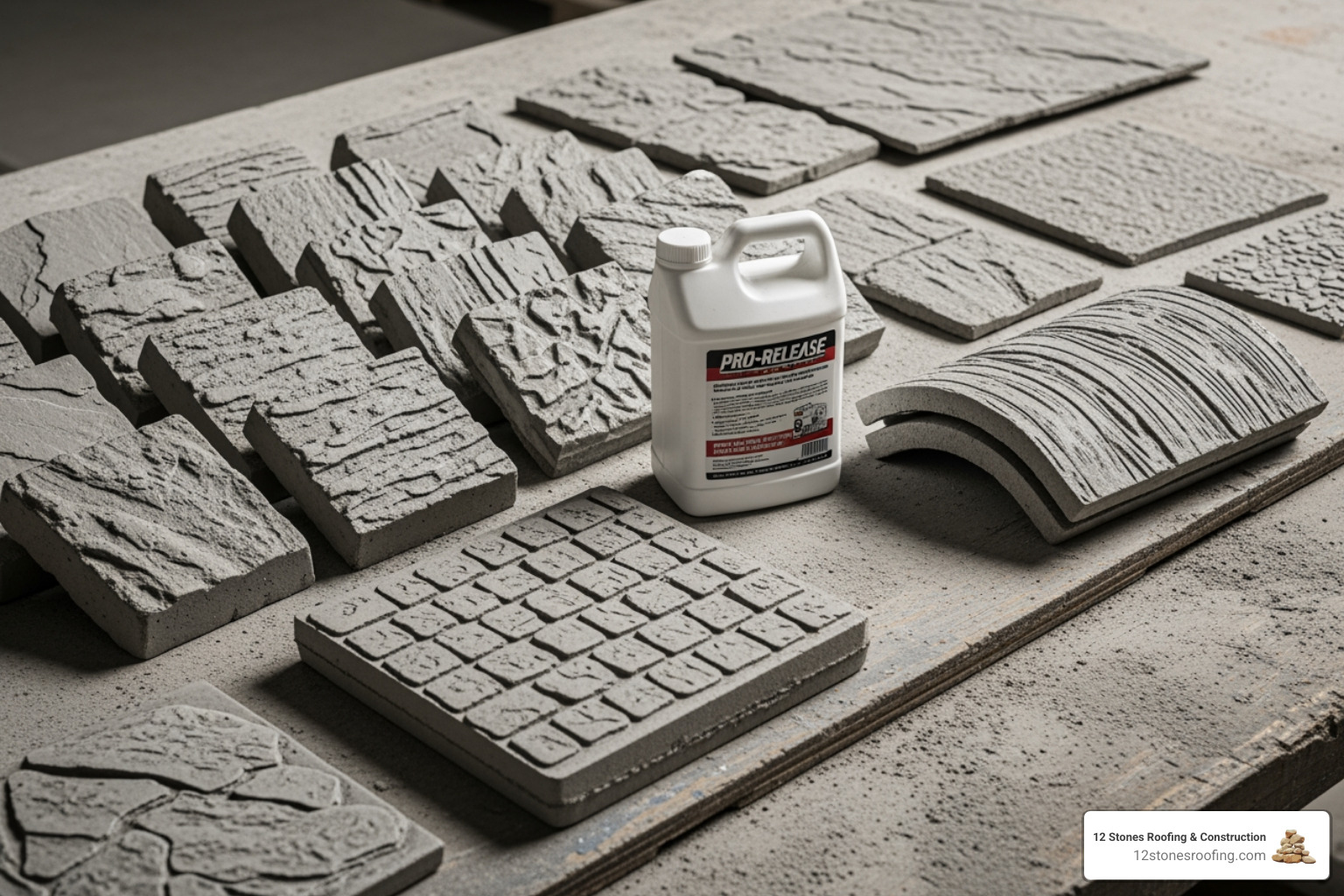

- Release Agents: Powdered or liquid agents that prevent stamps from sticking to wet concrete. Powdered versions also add a secondary, antiquing color.

- Concrete Stamps: Urethane mats molded from real slate. Rigid stamps cover the main area, while floppy stamps are flexible for edges and corners.

- Texture Skins: Smaller mats for touching up missed spots.

- Trowels and Edgers: Standard tools for smoothing and shaping concrete before stamping.

- Pressure Washer: Used to clean off excess release agent after the concrete sets.

- Protective Sealer: A high-quality sealer is crucial for protecting the surface from stains and weather while enhancing its color. For an even more refined look, specialized polishing chemicals can be used.

Choosing Your Slate Pattern

The pattern you choose dramatically affects the final look. Popular options include:

- Ashlar Cut Slate: A classic, sophisticated pattern of rectangular or square tiles.

- Grand Ashlar: Uses larger, more varied rectangular and square stones for a bolder look on large surfaces.

- Roman Slate: Features irregular, organic shapes for an old-world, hand-chiseled aesthetic.

- Seamless Textures: Provides a continuous stone texture without distinct grout lines for a subtle, organic feel.

Match the pattern’s scale to your project and home’s architectural style for a cohesive design. For more ideas, browse design options for stone-like surfaces.

Exploring Color Options for Slate Look Concrete

Color is what brings slate look concrete to life. We layer different coloring techniques to achieve a realistic, multi-tonal appearance.

- Integral Colors: Mixed into the concrete for a base color that runs through the entire slab.

- Color Hardeners: Broadcast over the surface to add intense color and increase abrasion resistance.

- Antiquing & Release Agents: These powdered agents add a secondary color that settles into the textures, creating depth and a weathered look.

- Stains and Dyes: Applied after curing, these penetrate the concrete to create variegated, translucent effects that mimic natural stone.

The 7-Step Guide to Installing Slate Look Concrete

Creating a beautiful slate look concrete surface is a process where precision and timing are paramount. While some may consider it a DIY project, professional installation is the best way to guarantee the longevity and flawless aesthetic that makes this investment worthwhile. Here’s a walkthrough of how professionals bring these stunning surfaces to life.

1. Site Preparation & Forming

The first step is preparing the canvas. This involves excavating the area to the correct depth, ensuring proper drainage, and compacting the sub-base to prevent future settling or cracking. Sturdy formwork is then installed to define the precise shape of the new surface.

2. Pouring & Leveling

Next, the concrete mix is poured and distributed evenly. Using screeding tools, the concrete is leveled to the desired thickness and pitch. This ensures a uniform surface and proper water runoff, which is crucial for long-term durability.

3. Applying Color & Release Agent

This is where the artistry begins. If an integral color is used, it’s already in the mix. A color hardener may be broadcast over the surface for vibrant color and added strength. Then, a release agent is applied to prevent stamps from sticking and to add a secondary, antiquing color.

4. The Stamping Process

Timing is critical. When the concrete reaches a “doughy” consistency—firm enough to support weight but soft enough to take an impression—the stamping begins. We interlock rigid stamps and press them into the concrete to create the slate look concrete pattern, using flexible stamps for edges and tight corners.

5. Detailing & Cutting Joints

After stamping, we use smaller touch-up skins to refine any imperfections. Equally important is cutting control joints. These are strategically placed cuts that guide natural cracking as the concrete expands and contracts, preventing random, unsightly fractures.

6. Washing & Curing

After 24 to 48 hours, the surface is washed with a pressure washer to remove excess release agent, revealing the true colors and texture. The concrete then needs to cure—a chemical process where it gains its full strength, which can take several weeks.

7. Sealing the Surface

The final, essential step is applying a high-quality protective sealer. Two coats are typically applied to enrich the colors, protect the concrete from stains and UV damage, and add a layer of defense against the elements. This step is what ensures your slate look concrete maintains its beauty for years.

Long-Term Care, Cost, and Applications

An investment in slate look concrete pays dividends in beauty and functionality for decades. Understanding its maintenance, cost, and best uses is key to maximizing its value and ensuring your outdoor space remains a source of pride.

Maintaining Your Stamped Concrete Surface

One of the biggest draws of slate look concrete is its low maintenance. A little care goes a long way in preserving its appearance and extending its lifespan beyond 25 years.

- Routine Cleaning: Regularly sweep the surface to remove debris. For a deeper clean, use a mild detergent, a soft brush, and a rinse with a garden hose.

- Periodic Resealing: This is the most crucial task. Resealing every 2 to 3 years is recommended to maintain protection against UV rays, moisture, and stains. This preventative step, much like following a Roof Maintenance Checklist, saves money on future repairs.

- Winter Care: Avoid using de-icing salts, which can damage the concrete. Sand is a much safer alternative for traction during icy conditions.

Cost of Slate Look Concrete vs. Natural Slate

This is where slate look concrete truly shines as a smart investment. It costs significantly less than natural slate due to lower material and labor expenses. Laying individual slate pavers is a slow, meticulous process, whereas stamping concrete is much faster.

- Natural Slate: Typically ranges from $15-$30 per square foot.

- Slate Look Concrete: Generally falls between $8-$18 per square foot.

The long-term value is also exceptionally high due to its durability and low maintenance needs, making it an economical choice that doesn’t compromise on aesthetics.

Popular Applications for a Slate Finish

The versatility of slate look concrete allows it to improve almost any outdoor space. Its combination of sophisticated texture and concrete’s strength makes it ideal for a wide array of applications.

- Patios and Outdoor Living Spaces: Creates a luxurious and inviting area for entertaining.

- Walkways and Garden Paths: Adds instant curb appeal and guides guests with sophistication.

- Pool Decks: Offers a beautiful, non-slip surface when a grip additive is included in the sealer.

- Driveways: Provides a durable and aesthetically pleasing first impression that withstands vehicle traffic.

- Interior Floors: Can be used in basements or sunrooms for a durable, rustic-chic look.

Frequently Asked Questions about Slate Stamped Concrete

Many homeowners have questions about slate look concrete before starting a project. Here are straightforward answers to some of the most common inquiries.

Can you stamp over an existing concrete slab?

Yes, you can apply a stamped overlay to an existing concrete slab, provided it is structurally sound (free of major cracks or heaving). The process involves applying a bonding agent and then a specialized concrete overlay mixture, typically 1/2″ to 3/4″ thick. Once the overlay is applied, it can be stamped with your chosen slate look concrete pattern. This method is a cost-effective way to transform an old patio or driveway without the disruption of a full tear-out and replacement.

How do you prevent stamped concrete from being slippery?

Preventing a slippery surface is a critical safety measure, especially for pool decks and walkways. The solution is to add a non-slip additive directly into the final sealer coat. This additive is a fine, gritty polymer or silica sand that creates a subtle texture on the surface, significantly increasing traction when wet. This process does not alter the visual appearance of the slate pattern but provides essential grip for peace of mind.

How long does slate look concrete last?

When installed correctly and properly maintained, slate look concrete can easily last 25 years or more. Its longevity often surpasses that of other materials like asphalt, which requires more frequent repairs, or pavers, which are prone to shifting and weed growth. The inherent strength of concrete, combined with the protective barrier of a quality sealer, creates a surface that stands up remarkably well to Texas weather and daily use. Consistent maintenance, primarily resealing every 2-3 years, is the key to ensuring this long lifespan.

Conclusion: Achieve a High-End Look That Lasts

Slate look concrete delivers an exceptional combination of timeless beauty, rock-solid durability, and genuine value. For homeowners in Pasadena, TX, it is a smart investment that improves curb appeal while standing strong against intense sun and humidity for 25 years or more.

This technique provides the sophisticated aesthetic of high-end stone without the financial burden or maintenance headaches of natural slate. You get the look of hand-hewn stone, the strength of concrete, and the peace of mind that comes from a surface built to last.

At 12 Stones Roofing & Construction, we know that quality installation is paramount for performance, whether it’s the surface under your feet or the roof over your head. To create a truly cohesive and high-quality appearance for your property, consider complementing your new concrete with the authentic beauty and longevity of Slate Roofing.

Ready to discuss your exterior improvement project? Whether you’re planning a stunning new surface or need expert advice on protecting your home with a quality roof, our team is here to help. Contact us for a professional consultation to build and protect the home you love.