Why Commercial Metal Roof Repair Demands Expert Attention

Commercial metal roof repair is a specialized service that protects your property investment and business operations from water damage, structural issues, and rising energy costs. When your metal roof shows signs of damage, choosing the right repair partner means the difference between a quick fix and a long-term solution that extends your roof’s lifespan by decades.

Quick Answer: What You Need for Commercial Metal Roof Repair

- Professional inspection to identify all damage (not just visible leaks)

- Licensed contractor experienced with metal roofing systems

- Proper repair methods for your specific metal roof type (standing seam, corrugated, etc.)

- Quality materials including rust inhibitors, sealants, and fasteners

- Preventive maintenance plan to avoid future costly repairs

Metal roofs can last 30 to 60 years, but only if repairs are done correctly. Targeted repairs addressing specific issues like fastener problems can save property owners thousands compared to unnecessary full replacements.

In Texas, severe weather creates unique challenges. Metal expands and contracts with temperature changes—over a 120-foot roof with a 100-degree temperature swing, thermal movement can reach one full inch. This constant stress loosens fasteners, separates seams, and accelerates wear.

For Pasadena commercial properties, prompt action matters. Water infiltration compromises insulation, creates mold, destroys inventory, and disrupts operations. A small leak today can become structural damage tomorrow. That’s why our team specializes in commercial metal roof repair for Texas businesses, combining manufacturer certifications with hands-on knowledge of local building codes and climate challenges.

7 Critical Signs Your Commercial Metal Roof Needs Immediate Repair

Even the toughest commercial metal roofs show signs of distress. Catching these warnings early is the difference between a straightforward commercial metal roof repair and a crisis that shuts down operations. Most major roof failures start with small, ignored signs. Here are seven critical indicators that your roof needs immediate professional attention from a commercial roofing expert.

Leaks and Water Stains

Water stains on ceilings or walls are clear alarm bells. When you spot discoloration, peeling paint, or dripping, your roof is compromised. Water can travel along panels and beams before appearing, meaning the leak source may be far from the visible stain. This moisture saturates insulation, feeds mold, and corrodes unseen metal components.

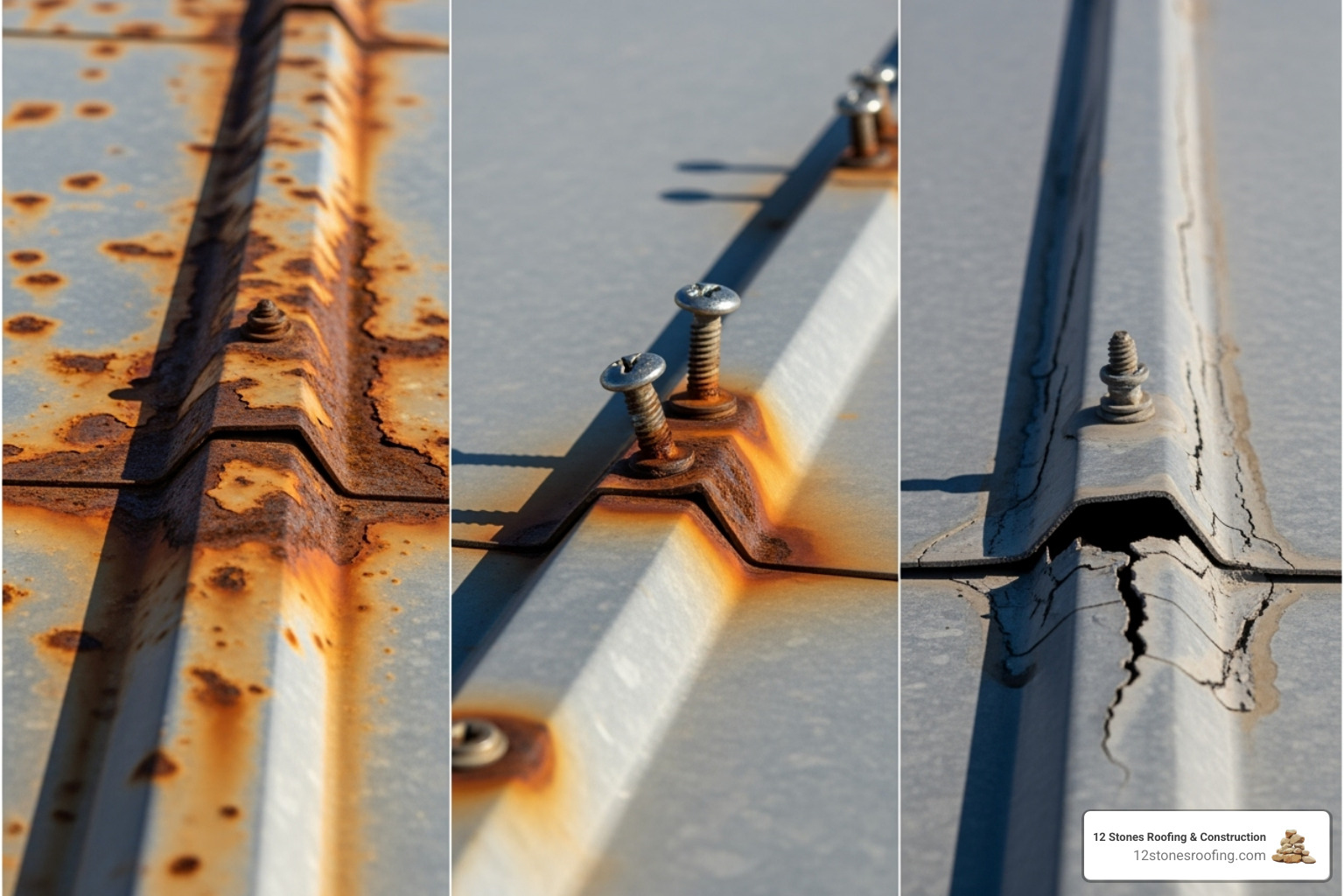

Rust and Corrosion

Rust is metal roof cancer; it starts small and spreads if not treated. In Texas’s humid climate, moisture breaks down protective coatings, causing reddish-brown patches (rust) or white powdery buildup (corrosion). What begins as a surface issue can eat through the metal, leading to holes and leaks.

Loose or Missing Fasteners

Fastener failure is a common and often invisible problem from the ground. Thermal expansion and contraction constantly work screws loose. Wind uplift adds stress, and foot traffic can disturb them. When fasteners back out or go missing, they create direct leak paths and allow panels to shift or detach in severe weather.

Separated Seams or Panels

The seams where metal panels connect are vulnerable points. Thermal movement, installation errors, and weather stress can cause them to separate. In standing seam systems, concealed clips can fail, while corrugated panels show more obvious gaps. Even a small opening allows water to rush in, and the stress on adjacent panels accelerates failure.

Bubbling or Peeling Coatings

Your roof’s protective coating acts like sunscreen. When elastomeric and acrylic coatings bubble, peel, or delaminate, the metal is exposed. UV radiation breaks down the metal’s surface, heat accelerates oxidation, and moisture starts the rust cycle. This also causes your energy bills to climb as the roof absorbs more heat.

Ponding Water

Water sitting on your roof for more than 48 hours after rain is a sign of a problem. Ponding water indicates structural issues like sagging panels, inadequate drainage, or clogged scuppers. This stagnant water accelerates corrosion, degrades coatings, and adds significant weight stress to the structure.

Unexplained Increases in Energy Bills

Rising energy costs can trace back to compromised roof integrity. When moisture saturates insulation, its R-value drops, forcing your HVAC system to work harder. Failed coatings also absorb heat instead of reflecting it, turning your building into an oven. Addressing roof issues can cut energy bills by 20-30%.

The Role of Thermal Expansion in Metal Roof Repairs

Metal expands in heat and contracts in cold. This thermal expansion is the primary force behind most metal roof wear, especially in Texas. A 120-foot steel panel can move a full inch during a 100-degree temperature swing, creating constant stress.

- Fasteners bear the brunt, gradually backing out or elongating their holes.

- Panels can warp or buckle if they cannot move freely, a condition known as oil-canning.

- Seams suffer the most, as sealants crack and lose adhesion from repeated stretching.

Proper installation with floating clips and expansion joints is designed to accommodate this movement. Regular inspections are crucial to catch thermal-induced damage before it leads to major failure. Understanding these dynamics is the foundation of an effective commercial metal roof repair strategy. Learn more about roof repair solutions that address these challenges.

Common Types of Metal Roof Damage in Commercial Buildings

Commercial metal roofs are tough, but they face constant challenges. Understanding the specific types of damage helps in responding quickly and effectively.

- Punctures and Tears: Surprisingly common, these can be caused by falling branches, dropped tools during HVAC maintenance, or even heavy foot traffic wearing down protective coatings.

- Corrosion and Rust: A relentless issue in humid climates like the Gulf Coast. When protective coatings fail or water ponds, rust takes hold, weakening the metal and leading to holes and leaks. Salt air and industrial pollutants can accelerate this process.

- Fastener Failure: Thermal movement loosens screws over time, while UV exposure degrades the rubber washers that provide a seal. Over-tightened or under-tightened fasteners from the initial installation are also common points of failure.

- Sealant Degradation: Sealants at seams and flashings are a primary defense, but they dry out, crack, and shrink under constant UV exposure. Once a sealant fails, it creates a direct path for water.

- Panel Damage: Severe hail can dent or even fracture metal panels. High winds can lift, bend, or tear panels, especially at corners and edges. The Panel Repair Technical Bulletin | MBCI offers technical guidance on these issues.

Repairing Standing Seam vs. Corrugated Metal Roofs

Not all commercial metal roof repair is the same; the approach depends on the system.

Standing seam systems feature raised, interlocked seams with concealed fasteners. This design offers superior weather protection but makes leak detection and repair more complex. Panel replacement requires special tools to disengage adjacent panels without causing damage. Seam repair involves re-crimping or applying high-grade sealants into the seam channel.

Corrugated or R-panel systems use exposed fasteners that go directly through the panels. While this makes installation faster, the fasteners are the most common source of leaks. The good news is that repairs are more straightforward. We can quickly replace failed screws with new, oversized gasketed ones. Seam sealing involves applying sealant or tape to the overlapped joints.

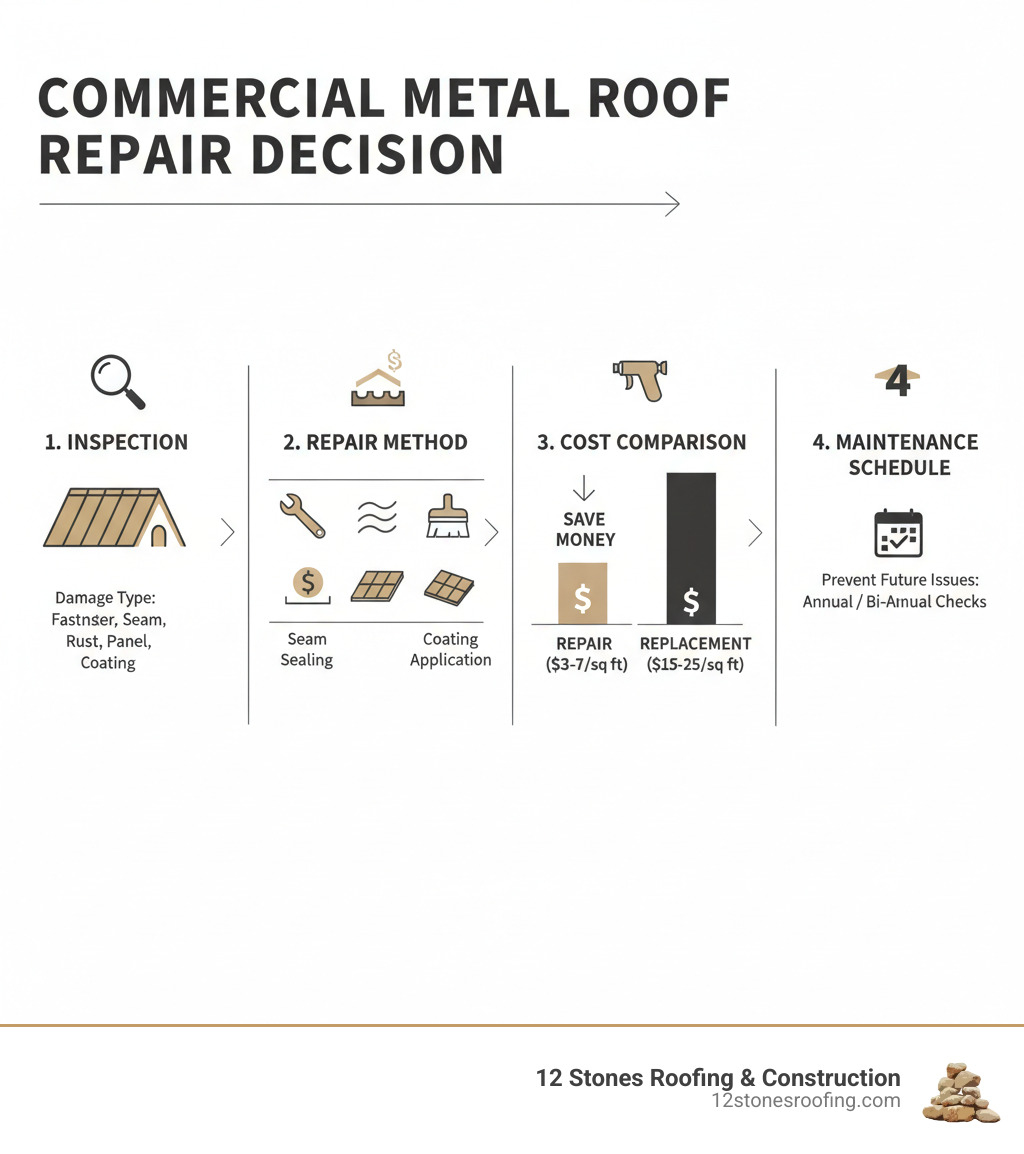

Step-by-Step Guide to Commercial Metal Roof Repair

While a small leak might seem like a simple DIY patch, commercial metal roof repair is far more complex than residential roofing. Different metal types, coatings, and installation methods require specialized knowledge. An improper repair can void your warranty or create bigger problems. A professional assessment identifies the root cause, ensuring a lasting solution.

Commercial Metal Roof Repair Process

Our systematic approach ensures every repair is thorough and effective.

-

Safety and Inspection: We begin by implementing strict OSHA-compliant safety protocols, including fall protection. A comprehensive inspection follows, where we document everything from obvious leaks to subtle signs of stress like loose fasteners or bubbling coatings. We check gutters, flashings, and all roof penetrations.

-

Surface Preparation: This is a critical step. We remove all debris, dirt, and loose material. For rusted areas, we mechanically remove all corrosion down to bare metal using wire brushes or grinders. The area is then cleaned and dried completely, as applying sealants over a contaminated surface will lead to premature failure.

-

Repair Execution: We use specialized techniques for each type of damage:

- Fastener Repair: Loose screws are tightened to the correct torque. Corroded or stripped fasteners are replaced with new, oversized, weather-resistant screws with durable EPDM gaskets for a watertight seal.

- Seam Sealing: We apply high-grade elastomeric or silicone sealant to compromised seams, often reinforcing them with specialized tape for added durability.

- Rust Treatment: After removing rust, we apply a rust-inhibiting primer to prevent recurrence, followed by a matching topcoat for protection.

- Panel Patching/Replacement: Small punctures are patched with metal and sealed. Severely damaged panels are replaced, matching the original material, profile, and color as closely as possible.

-

Protective Coatings: For roofs with widespread aging, a fluid-applied acrylic or silicone coating can be a great solution. This creates a seamless, waterproof membrane that restores the roof, improves energy efficiency, and can add 10-20 years to its life.

-

Final Inspection and Maintenance Planning: After repairs, we conduct a final quality check, including water tests on critical areas. We then work with you to schedule regular maintenance, which is the key to maximizing your roof’s lifespan and preventing future emergencies.

Repair vs. Replacement: Making the Right Investment for Your Roof

When your commercial metal roof is damaged, you face a key decision: repair or replace? The right choice depends on your roof’s age, the extent of the damage, and long-term financial sense. Think of it like an old car—minor issues are worth fixing, but you don’t pour money into a failing engine.

When to Choose Repair

Repair is the best option when damage is localized and the roof is structurally sound. If you’re dealing with a few loose fasteners, a separated seam, or minor rust, targeted commercial metal roof repair is highly effective.

- Best for roofs under 20 years old.

- Cost-effective for budget constraints. Restoration often costs $3–$10 per square foot.

- Ideal for minor leaks, fastener issues, and coating wear.

Roof restoration systems are a powerful repair option. If the metal is sound but the surface is aged, a fluid-applied coating can add 10-20 years of life for a fraction of the cost of replacement.

When to Consider Replacement

Full replacement is the right investment when damage is widespread or the roof has reached the end of its life.

- Necessary when over 25% of the roof is compromised by rust, hail, or deterioration.

- Required for structural integrity issues like widespread corrosion or buckling panels.

- The best solution for recurring leaks despite multiple repair attempts.

- A wise choice when a roof is past its 25-50 year expected service life.

Replacement costs are higher upfront—typically $15–$25+ per square foot—but it provides a brand-new system with a new warranty and decades of reliable performance.

| Option | Cost per sq ft | Expected Lifespan (added) | Operational Impact | Solves Major Issues | Improved Insulation | Improved Reflectivity | Warranty Coverage |

|---|---|---|---|---|---|---|---|

| Repair (Targeted) | Varies, minor | Remaining roof life | Low | Specific damage | No | No | Limited to repair |

| Restoration (Coating/Foam) | $3–$10 | 10–20 years | Low | Yes | Yes (Foam) | Yes | 10-20 years (coating thickness dependent) |

| Full Replacement | $15–$25+ | 25–50+ years | High | Yes | Yes | Yes (material dependent) | New system warranty |

An honest, professional assessment is key. We evaluate every roof individually to help you make the decision that best protects both your building and your budget.

The Importance of Proactive Maintenance and Expert Service

Addressing commercial metal roof repair needs promptly is about protecting your entire operation. A small, ignored leak can saturate insulation, drive up energy bills, promote mold growth, and eventually compromise your building’s structural integrity. Proactive maintenance is your roof’s best defense, identifying minor wear before it becomes a critical failure. This approach prevents expensive emergencies and significantly extends your roof’s lifespan.

How to Select the Best Commercial Metal Roof Repair Contractor

Choosing the right contractor is as crucial as the repair itself. Look for a partner with:

- Specialization in Commercial Metal Roofing: Experience with the unique requirements of metal systems is non-negotiable.

- Proper Licensing and Insurance: Ensure they are licensed in Texas and carry full liability and workers’ compensation insurance.

- Local Code and Climate Familiarity: A local contractor in the Pasadena, TX area will understand regional building codes and hurricane preparedness standards.

- Detailed, Transparent Estimates: A reputable contractor provides a clear, written scope of work, materials, and costs.

- Strong Workmanship Warranties: This demonstrates confidence in their installation quality.

- Positive Local Reviews: Check references from other commercial clients. For trusted service, see what businesses say about roofers near me in Houston.

Preventive Maintenance: Your Roof’s Best Defense

Preventive maintenance is an investment that pays for itself. A typical plan includes:

- Biannual Inspections: Professional checks in spring and fall to catch issues early.

- Gutter and Drain Cleaning: Prevents ponding water, which accelerates corrosion.

- Debris Removal: Removes trapped moisture and prevents surface damage.

- Seam and Flashing Checks: Inspecting and re-sealing these common failure points.

A well-maintained metal roof can easily last 50 years or more, maximizing your investment. For a complete guide, Download our Roof Maintenance Checklist.

Frequently Asked Questions about Commercial Metal Roof Repair

How long does a commercial metal roof repair last?

The longevity of a repair depends on the method and materials. Professional repairs, such as replacing fasteners or properly sealing seams, can last for the remaining life of the roof. A fluid-applied restoration coating can add 10–20 years of life. Patch repairs for minor punctures typically last several years but should be monitored during regular maintenance.

Can you apply a coating over a rusted metal roof?

No. Applying a coating directly over rust is a critical mistake that guarantees failure. The rust will continue to spread underneath, causing the coating to bubble and peel. The correct process is to mechanically remove all rust down to bare metal, clean the surface, apply a rust-inhibiting primer, and only then apply the final protective coating.

How much does commercial metal roof repair cost?

Costs for commercial metal roof repair vary widely based on the scope of work.

- Minor Repairs: Tightening fasteners or sealing a small leak can cost a few hundred dollars.

- Restoration: A silicone coating system typically costs $3–$7 per square foot. A spray foam system, which adds insulation, averages $5–$10 per square foot.

- Full Replacement: This is the largest investment, ranging from $15–$25+ per square foot, but it provides a completely new roof system with a long-term warranty.

An accurate estimate requires a professional inspection of your specific roof’s condition.

Protect Your Pasadena Business with a Proven Roofing Partner

Your commercial metal roof is a critical asset that protects your business operations and bottom line. From minor fastener issues to widespread aging, taking decisive action with the right partner can save you thousands in the long run.

At 12 Stones Roofing & Construction, we understand that commercial metal roof repair is about diagnosing the root cause and applying a lasting solution. We know the Texas climate and how heat, humidity, and severe weather stress metal roofing systems. Our approach is built on providing specialized expertise for every project, whether it’s a simple repair or a full restoration.

Every project begins with a thorough inspection and an honest assessment. We provide transparent, reliable service to help you choose the best path forward for your property. Our manufacturer certifications and adherence to the highest industry standards ensure your repair is done right, protecting your warranty and your investment.

Don’t let a small problem like a leak or rust spot become a business crisis. The longer you wait, the more complex and expensive the solution becomes. If you’ve noticed any warning signs, it’s time for a professional assessment.

Safeguard your investment and keep your business running smoothly. Learn more about our commercial roofing services and schedule a comprehensive inspection. We’ll provide a detailed assessment and a clear plan to ensure your roof is ready to protect your business for years to come.