EPDM Membrane Windows: The Hidden Weather Barrier Protecting Texas Buildings

EPDM membrane windows create a continuous, weatherproof, and airtight seal between window frames and the surrounding structure, preventing water intrusion, uncontrolled air leakage, and energy loss. Buildings that incorporate EPDM sealing around fenestrations routinely cut air leakage by more than 50% compared to unsealed or poorly sealed openings, according to multiple building envelope performance studies. For property owners who want a durable, whole-building solution, integrating EPDM window membranes with a professionally designed roofing system from a specialized contractor like Texas roofing experts for long‑lasting protection delivers one of the highest returns on building envelope upgrades over a 20–30 year horizon.

As a leading provider of expert roofing and construction in Pasadena, TX, we know that a properly sealed building envelope is the first line of defense against the elements. Here’s what you need to know about this critical component:

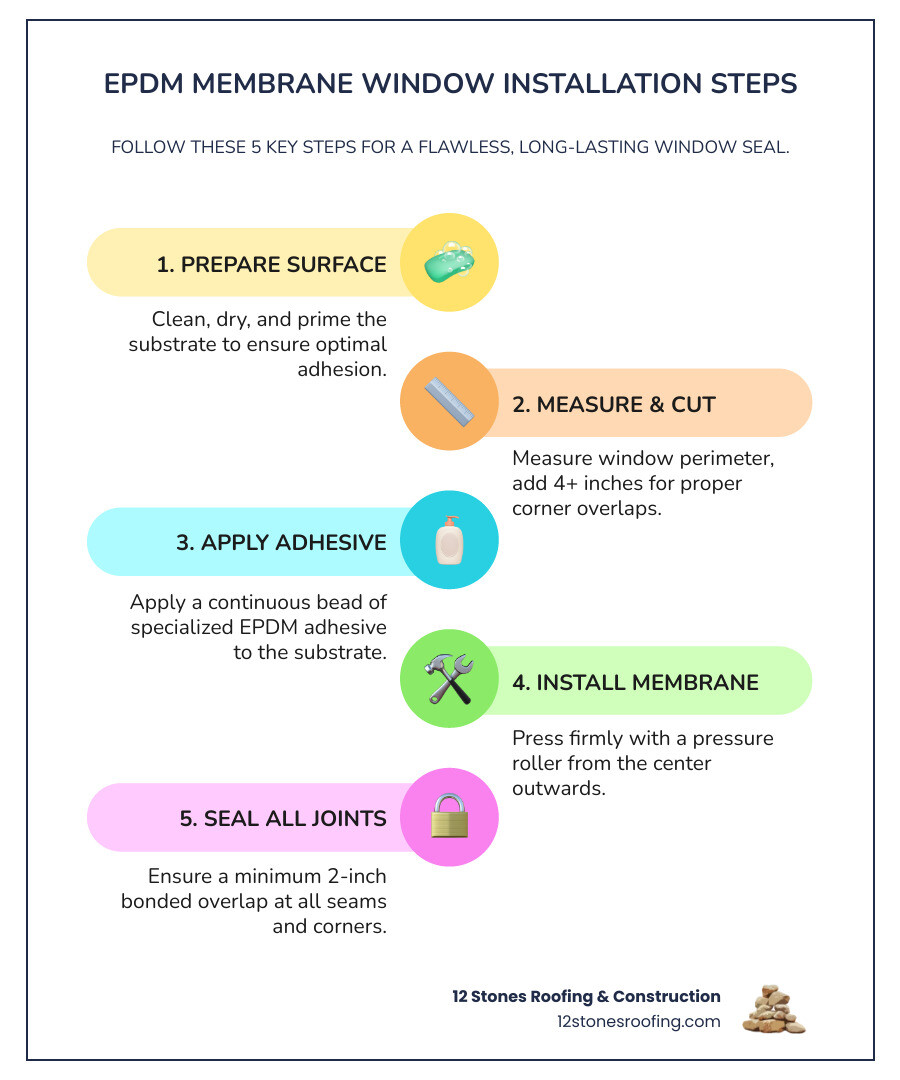

Quick Installation Overview:

- Prepare the surface – Clean, dry, and prime the substrate

- Measure and cut – Add 4+ inches to each end for proper overlap

- Apply adhesive – Use specialized EPDM adhesive in a continuous bead

- Install membrane – Press firmly with a roller, working from center outward

- Seal corners and overlaps – Ensure at least 2-inch bonded overlap at joints

Key Benefits:

- Durability: 40-50+ year lifespan with minimal maintenance

- Temperature resistance: Remains flexible from -40 F to +248 F

- Weather protection: Excellent UV, ozone, and moisture resistance

- Airtightness: Meets EN 12114 standards (<0.1m b3 air leakage)

- Watertightness: Passes EN 1928 (2 kPa for 24 hours)

For Texas property owners, EPDM membrane windows are particularly valuable. Our Gulf Coast climate delivers extreme heat, intense UV exposure, heavy rainfall, and occasional freeze eventsall conditions that EPDM handles exceptionally well. A properly installed EPDM window seal protects against the severe weather damage that frequently impacts Pasadena-area properties, preventing costly water intrusion and the subsequent mold growth that thrives in our humid climate.

Whether you’re dealing with new construction, window replacement, or facade renovation, understanding EPDM installation ensures your building envelope performs as designed. For comprehensive protection, this window sealing should be part of a fully integrated weatherproofing system that includes a well-maintained roof.

I’m Jason Roberts, owner of 12 Stones Roofing & Construction, and over the past decade I’ve overseen countless installations involving EPDM membrane windows and specialized waterproofing systems throughout the Pasadena area. My hands-on experience with Gulf Coast weather challenges has taught me that proper window sealing is just as critical as the roof itself when it comes to protecting your property investment.

Understanding EPDM: The Ultimate Sealant for Windows and Facades

EPDM, or Ethylene Propylene Diene Monomer, is a synthetic rubber elastomer that has been a workhorse in construction and industrial engineering for over 50 years. Its unique molecular structure gives it an exceptional range of properties that make it an ultimate choice for sealing critical junctions in buildings, especially around windows and facades.

When we talk about EPDM, we’re talking about a material that truly stands the test of time and elements. It’s renowned for its incredible flexibility, allowing it to move with the building as it expands and contracts due to temperature fluctuations, without cracking or becoming brittle. This is crucial in our Texas climate, where temperatures can swing dramatically. EPDM remains flexible across a vast range, from a chilling -40°F to a scorching +248°F (-40 to +120°C), ensuring a consistent seal year-round.

Its durability is legendary, with membranes capable of lasting at least 40 years, and often over 50 years in exposed installations. This longevity is backed by its high resistance to weathering, UV radiation, and ozone, which are common culprits in degrading other sealing materials. Furthermore, EPDM offers excellent watertightness, able to withstand 2 kPa of water pressure for 24 hours (EN 1928), and superior airtightness, with air leakage rates typically less than 0.1m³ (EN 12114). These properties combine to create a robust, long-lasting barrier that keeps your building dry and energy-efficient.

What Makes EPDM a Superior Weatherproofing Material?

EPDM is a high-density synthetic rubber known for its incredible resilience. Its molecular structure gives it superior resistance to weathering, UV radiation, and extreme temperatures, making it a perfect choice for sealing the building envelope. Unlike other materials that can become brittle over time, EPDM remains flexible for decades, accommodating the natural expansion and contraction of building materials without cracking or failing. This ensures a continuous, long-lasting airtight and watertight seal around your windows and facades.

But EPDM’s superiority goes beyond just flexibility and weather resistance. It boasts a high linear elongation, meaning it can stretch by up to 300% in some directions and over 100% in others without losing its integrity. This elasticity allows it to compensate for significant thermal and structural movements that buildings constantly experience, preventing stress on the seals. It’s also highly resistant to various chemicals, pollutants, and even biological factors like rodents, fungi, and bacteria, making it a truly resilient material for any building project.

The ability of EPDM to act as an excellent moisture vapor barrier is also a key advantage. While we’ll discuss vapor management in more detail later, its inherent resistance to water and moisture penetration means it effectively blocks external elements from entering your building’s sensitive internal structure. This comprehensive protection is why we at 12 Stones Roofing & Construction often recommend EPDM for critical sealing applications, providing a reliable shield against the unpredictable Texas weather.

Gearing Up: Tools and EPDM Membrane Types for Your Project

Before we dive into the nitty-gritty of installation, let’s talk about getting prepared. Just like any successful project, having the right materials and tools on hand makes all the difference. When it comes to EPDM membrane windows, there are a few types of membranes and essential accessories you’ll need to consider.

Here’s a list of essential tools and materials for your EPDM membrane installation:

- EPDM membrane (chosen type)

- Specialized EPDM adhesive (for non-self-adhesive membranes)

- EPDM primer (for porous or difficult substrates)

- Utility knife and measuring tape

- Pressure roller

- Sealant gun (for adhesive application)

- Cleaners (for surface preparation and adhesive residue)

- Gasket carrier (if using gasketed membranes)

- Safety gloves and glasses

Ensuring every part of your property is protected, from the windows to the roof, is crucial for long-term durability and peace of mind.

Choosing the Right Type of EPDM Membrane

Not all EPDM membranes are created equal. For window applications, you’ll primarily encounter three types:

- Self-Adhesive: These membranes come with a pre-applied adhesive backing, simplifying and speeding up the installation process. They are ideal for smooth, clean substrates, offering a quick and efficient seal. Products like some versions of illbruck ME220 EPDM film are available with self-adhesive backing.

- Gasketed: Some EPDM membranes, such as the OBEX CORTEX EPDM Membrane With Gasket, feature an integrated gasket designed to slot directly into the channel of a window frame. This creates a secure mechanical fix that’s not affected by low application temperatures or damp substrates, which can be a real game-changer. This type is also compatible with various window systems like Schuco, Reynaers, Aluprof, and Senior.

- Non-Adhesive: This is the traditional format, requiring a separate application of a specialized EPDM adhesive. While it adds an extra step, it offers incredible versatility for bonding to various, and sometimes uneven, substrates, such as blowholes in concrete. For non-self-adhesive illbruck ME220 EPDM film, for example, you’d use a specific EPDM foil adhesive or CT113 adhesive.

EPDM membranes also come in different thicknesses depending on the application. A common thickness for door and window sealing might be 1.2mm, while a thinner 0.75mm EPDM film is often used for facade sealing. Our team can help you select the precise type and thickness required for your specific project, ensuring optimal performance and longevity.

The Ultimate Guide to Installing EPDM Membrane Windows

Installing EPDM membrane around windows is a precise job, but with careful attention to detail, it can yield outstanding results. We’ve seen how a properly executed installation can save homeowners and businesses a world of trouble down the line.

Step 1: Surface Preparation is Key

A successful installation begins with a pristine surface. The substrate (wall and window frame) must be structurally sound, clean, dry, and completely free of dust, grease, oil, and loose particles. Think of it like preparing a canvas for a masterpiece – any imperfections will show through! For porous surfaces like concrete or wood, applying a specialized EPDM primer is crucial to ensure a strong, permanent bond. This primer creates an optimal surface for the adhesive to grab onto, preventing premature failure. For instance, when applying EPDM membrane on an existing roof covering or a concrete substrate, an EPDM special primer is often required.

Step 2: Measuring and Cutting the EPDM Membrane for Windows

Measure the perimeter of your window and add at least 4 inches (10 cm) to each end for creating a proper overlap at the corners. This extra material is essential for forming a seamless, waterproof “pig’s ear” or “bird’s mouth” fold at each corner, which is a critical detail for preventing water ingress. This overlap should ideally be 5 to 10 cm for corners. Cut the membrane to size using a sharp utility knife. It’s always better to cut a little too much than too little – EPDM is incredibly forgiving, but you can’t add material once it’s cut!

Step 3: Applying Adhesives and Installing the EPDM Membrane for Windows

If using a non-adhesive membrane, or for overlapping sections, applying the adhesive correctly is vital. We recommend starting the installation at the bottom of the facade element and working upwards, which helps with drainage. For the main bond, apply a continuous bead of EPDM adhesive to the substrate, typically 5 to 6 mm thick. Then, spread this bead to about 4-5 cm wide and 1 mm thick to ensure even coverage.

Install the membrane tension-free, allowing enough slack to accommodate structural movement. This “tension-free” approach means the membrane can move without tearing or pulling away from the adhesive. Firmly press the membrane into the adhesive using a pressure roller, working from the center outwards to eliminate air bubbles and ensure a full, continuous bond. This pressing ensures the adhesive spreads to a thickness of 1-2 mm and a width of approximately 25 mm.

Overlapping sections should have at least a 2-inch (5 cm) bond with adhesive applied between the layers. For example, the SikaMembran® Outdoor plus system specifies a minimum 5 cm overlap. It’s also important to note that some adhesives allow for readjustment of the membrane within about 30 minutes after installation, giving you a window of opportunity to perfect your placement. If using specific adhesives like VI-PRO® EPDM CONTACT ADHESIVE 903 or 904, follow their specific consumption guidelines for optimal adhesion. After the facade element (like the window frame) is installed, any connection joints should be filled with suitable PU foam before the EPDM membrane is bonded to the structure, ensuring a complete seal. The bond can only be fully loaded after the adhesive has completely cured.

EPDM vs. The Competition: Why It’s the Superior Choice

When it comes to sealing windows and facades, EPDM isn’t the only player in the game. You’ll encounter other materials like butyl tapes and liquid sealants, and increasingly, “intelligent” membranes. While each has its merits, EPDM often stands out for its robust, long-term performance, especially in challenging environments like Pasadena, TX.

Butyl tapes offer good adhesion and a relatively quick seal, but they often lack the extreme flexibility and long-term UV resistance of EPDM, potentially becoming brittle or losing their elasticity over time. Liquid sealants provide a seamless application, but their durability and movement accommodation can vary greatly, and they may require specific curing conditions.

The more direct comparison often comes with “intelligent” membranes. These newer materials incorporate variable moisture vapor permeability, a feature that EPDM, being a vapor barrier, does not possess. This means intelligent membranes can adapt their permeability based on humidity levels, allowing moisture to escape the building envelope more effectively. This is particularly important for managing condensation risk. If a vapor-tight membrane like EPDM is placed in a “cold zone” within a wall assembly, it can trap moisture and increase the risk of interstitial condensation and mold growth.

However, EPDM still holds its own. For the “tighter inside than outside” principle in building physics (where the inner seal is more vapor-tight than the outer to allow moisture to dry out), EPDM can serve as an excellent internal airtight seal. An intelligent, vapor-open membrane can then be used externally to facilitate moisture escape. This combination ensures robust air and watertightness while effectively managing vapor. In fact, using EPDM on both internal and external layers without proper vapor management can lead to condensation issues. For a deeper dive into this comparison, you might find this article on Intelligent membranes vs EPDM explained insightful.

While EPDM’s price can fluctuate with volatile oil markets, it remains a cost-effective option given its exceptional durability and longevity. Intelligent membranes, while offering advanced vapor management, can sometimes come with a higher upfront cost.

[TABLE] EPDM vs. ‘Intelligent’ Membranes

| Feature | EPDM Membrane | ‘Intelligent’ Membrane |

|---|---|---|

| Vapor Permeability | Low (Vapor Barrier, Sd value ~3m) | Variable (Adapts to Humidity, allows moisture escape) |

| Durability | Extremely High (50+ years in exposed use) | High (Varies by product, often 25-50 years) |

| UV Resistance | Excellent (remains stable for decades) | Good to Excellent (can be exposed for months) |

| Installation | Straightforward, requires specific adhesives/primers or gasket | Often self-adhesive, can be more forgiving, solvent-free adhesives |

| Cost | Generally cost-effective, but sensitive to oil prices | Can be more expensive upfront, but potentially lower long-term due to performance |

| Best Use Case | External weather seal, internal air barrier, high movement joints | Dual internal/external use, complex moisture situations, critical condensation control |

Technical Specs, Lifespan, and Common Applications

When we choose materials for your property, we’re not just looking at what’s popular; we’re scrutinizing the technical specifications and certifications. This is especially true for EPDM membrane windows, where performance directly impacts the integrity and energy efficiency of your building.

Lifespan and Durability: A 50-Year Promise

One of the most compelling reasons to use EPDM is its remarkable longevity. With a proven track record of over 50 years in the construction industry, EPDM membranes can be expected to last for at least 40 years, and often much longer, with minimal maintenance. This durability makes it a “fit and forget” solution, providing peace of mind and long-term value. Imagine installing a sealing system that could outlive your mortgage! Its resistance to weathering, UV radiation, and ozone means it won’t degrade under the intense Texas sun or during our humid, rainy seasons. For any issues that may arise over time, it’s best to consult a professional for roof repair solutions.

Technical Specifications and Certifications to Look For

When selecting an EPDM membrane, look for products that meet key industry standards. Certifications like BBA (British Board of Agrément) and compliance with European Norms (EN) guarantee that the product has been rigorously tested for performance and quality. Key EN standards to look for include:

- EN 13984: 2011: This CE marking signifies suitability for waterproofing applications.

- EN 13501-1 Class E: This indicates the fire classification, ensuring the material meets certain fire retardant requirements.

- EN 1928: Confirms watertightness, often rated to withstand 2 kPa for 24 hours.

- EN 1931: Specifies water vapor permeability, with EPDM typically having a low sd value (e.g., 3m for SikaMembran® Outdoor plus).

- EN 12311-2: Measures tensile strength, indicating the material’s resistance to tearing (e.g., ≥7MPa for some products).

- EN 12114: Verifies airtightness, with high-performance membranes achieving <0.1m³ air leakage.

These certifications assure us that the EPDM membrane will perform as expected, providing a reliable seal. Common applications for EPDM membranes in window and facade sealing include curtain walls, ventilated facades, door sills, and even as a water barrier in foundation walls against rising dampness. However, it’s important to remember EPDM’s limitations: it’s generally not resistant to mineral oils, petroleum, benzene, fuel, or toluene, nor is it suitable for permanent immersion or standing water. Also, if perforated, it may not be resistant to driven rain at wind loads exceeding 0.8 kPa.

Frequently Asked Questions about EPDM Window Membranes

We often get asked a lot of questions about EPDM, and for good reason—it’s a fantastic material, but understanding its nuances is key to maximizing its benefits.

Can EPDM membranes be painted?

Generally, it is not recommended to paint EPDM. The membrane’s inherent flexibility and elasticity, while excellent for accommodating building movement, can cause paint to crack, peel, and flake off over time. Paint adhesion to rubber surfaces is also notoriously difficult. If a specific color is needed for aesthetic reasons, it’s best to look for pre-colored EPDM products, though these are less common than the standard black. Our advice? Let EPDM do what it does best—seal and protect—and integrate it discreetly into your building design.

Is EPDM an environmentally friendly choice?

Yes, EPDM is considered an environmentally friendly material, and we’re proud to use it. It is an inert substance that does not release harmful pollutants or plasticizers into the environment, making it a safe choice for both installation and long-term use. Its exceptionally long lifespan—often 50 years or more—significantly reduces the need for frequent replacement, which in turn minimizes waste and the consumption of new resources. At the end of its very long service life, EPDM is also recyclable, further contributing to its green credentials. Choosing EPDM is a choice for durable, sustainable construction.

What is the main cause of EPDM membrane failure?

Here’s a little secret from the pros: the most common cause of EPDM membrane failure is not the material itself, but improper installation. EPDM is incredibly robust, but even the strongest material can fail if not applied correctly. Poor surface preparation (not cleaning, drying, or priming adequately), inadequate adhesive coverage (missing spots or applying too thinly), or failing to properly seal seams and corners can all create pathways for air and water infiltration. This leads to leaks, energy loss, and potential structural damage. This highlights the immense importance of following best practices, having meticulous attention to detail, or, better yet, hiring a professional team like ours who understands the nuances of EPDM installation. Even the best materials need the best hands to perform at their peak!

Conclusion: Use EPDM to Build a Data‑Backed, Storm‑Ready Building Envelope

EPDM membranes offer an exceptional combination of durability, flexibility, and weather resistance for sealing windows and facades. When correctly specified and installed, EPDM window membranes routinely deliver service lives of 40–50 years while maintaining watertightness under at least 2 kPa of hydrostatic pressure and airtightness below 0.1 m b3 of air leakage (EN 12114). These metrics put EPDM among the highest-performing window sealing solutions available for mixed-humid climates like the Texas Gulf Coast.

By understanding its unique properties and following the correct installation procedures, you can create a robust, long-lasting barrier that dramatically improves your building’s energy efficiency and protects it from water damage for decades. From resisting the harsh Texas sun and torrential downpours to accommodating the natural shifts of your building, EPDM is a true champion of the building envelope.

While a DIY installation is possible for those with experience, the critical nature of window sealingand the costly consequences of failuremeans that a professional touch guarantees a flawless, long-lasting result. For expert advice and installation of high-performance building envelope solutions, the team at 12 Stones Roofing & Construction has the experience to ensure your property is protected. If you’re in Pasadena, TX, or the surrounding areas and looking for reliable sealing solutions, don’t hesitate to reach out through our website or by calling (281) 940-5337. Learn more about our specialized EPDM roofing services and secure your investment today.